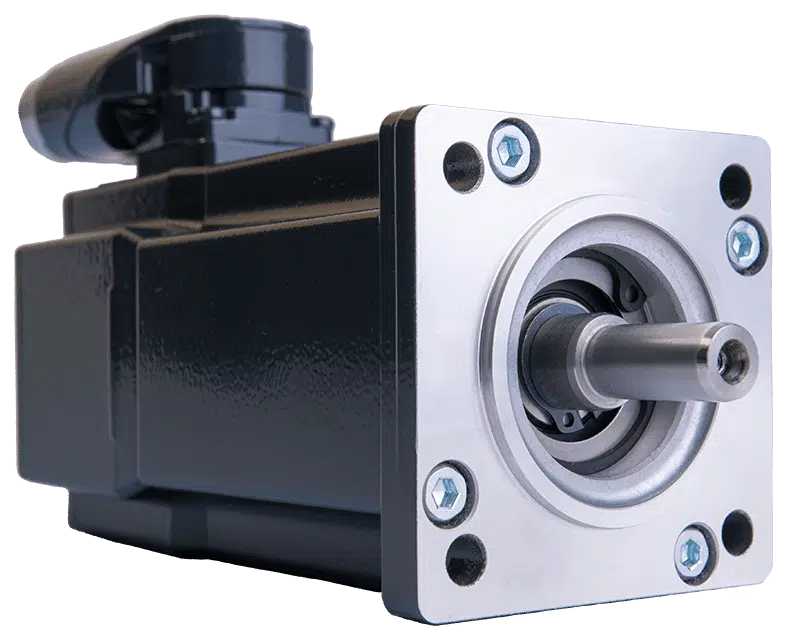

Product Description

| Product Name | Original Fanuc Ac Motor |

| Color | As Picture |

| Package | Standard Package |

| Quality | High-Quality |

About after-sales

01:

Company commitment

We have a complete set of FANUC testing equipment, ensuring that all products are brand new and genuine. Disassembled products are shipped after being tested by our engineers to be in good condition. After the testing is completed, we will provide you with a product inspection video. Disassembled products enjoy a 90 day warranty, and brand new products enjoy a 12 month warranty.

02:

About express delivery

We have a variety of personalized shipping channels that customers can choose from, such as UPS, DHL, FEDEX, etc. If you need specific instructions, please contact customer service guidance or make a record before shooting. If you specify a courier company, please contact our customer service as soon as possible before arranging shipment to avoid any delay in your use.

03:

Price Description

Our store has an absolute advantage in price for direct selling products from manufacturers! We guarantee that the store’s sales prices are worth it. Whether it’s brand new or second-hand, our prices are absolutely fair and transparent. Please rest assured to place your order. ZheZheJiang aohuangren Intelligent Technology Co., Ltd will be dedicated to serving you.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Package: | Standard Package |

|---|---|

| MOQ: | 1 Piece |

| Quality: | High-Quality |

| Color: | as Picture |

What role does the controller play in the overall performance of a servo motor?

The controller plays a crucial role in the overall performance of a servo motor system. It is responsible for monitoring and regulating the motor’s operation to achieve the desired motion and maintain system stability. Let’s explore in detail the role of the controller in the performance of a servo motor:

1. Motion Control:

The controller is responsible for generating precise control signals that dictate the motor’s speed, torque, and position. It receives input commands from the user or higher-level control system and translates them into appropriate control signals for the servo motor. By accurately controlling the motor’s motion, the controller enables precise positioning, smooth acceleration and deceleration, and the ability to follow complex trajectories. The controller’s effectiveness in generating accurate and responsive control signals directly impacts the motor’s motion control capabilities.

2. Feedback Control:

The controller utilizes feedback from position sensors, such as encoders, to monitor the motor’s actual position, speed, and other parameters. It compares the desired motion profile with the actual motor behavior and continuously adjusts the control signals to minimize any deviations or errors. This closed-loop feedback control mechanism allows the controller to compensate for disturbances, variations in load conditions, and other factors that may affect the motor’s performance. By continuously monitoring and adjusting the control signals based on feedback, the controller helps maintain accurate and stable motor operation.

3. PID Control:

Many servo motor controllers employ Proportional-Integral-Derivative (PID) control algorithms to regulate the motor’s behavior. PID control calculates control signals based on the error between the desired setpoint and the actual motor response. The proportional term responds to the present error, the integral term accounts for accumulated past errors, and the derivative term considers the rate of change of the error. By tuning the PID parameters, the controller can achieve optimal performance in terms of response time, stability, and steady-state accuracy. Properly configured and tuned PID control greatly influences the servo motor’s ability to follow commands accurately and efficiently.

4. Trajectory Planning:

In applications requiring complex motion profiles or trajectories, the controller plays a vital role in trajectory planning. It determines the optimal path and speed profile for the motor to follow, taking into account constraints such as acceleration limits, jerk limits, and mechanical limitations. The controller generates the required control signals to achieve the desired trajectory, ensuring smooth and precise motion. Effective trajectory planning by the controller enhances the motor’s performance in applications that involve intricate or high-speed movements.

5. System Monitoring and Protection:

The controller monitors various parameters of the servo motor system, including temperature, current, voltage, and other diagnostic information. It incorporates protective measures to prevent damage or excessive stress on the motor. The controller can implement safety features such as overcurrent protection, over-temperature protection, and fault detection mechanisms. By actively monitoring and safeguarding the motor and the system, the controller helps prevent failures, prolongs the motor’s lifespan, and ensures safe and reliable operation.

6. Communication and Integration:

The controller facilitates communication and integration with other components or systems within the overall automation setup. It may support various communication protocols, such as Ethernet, CAN bus, or fieldbus protocols, enabling seamless integration with higher-level control systems, human-machine interfaces (HMIs), or other peripheral devices. The controller’s ability to efficiently exchange data and commands with other system components allows for coordinated and synchronized operation, enhancing the overall performance and functionality of the servo motor system.

In summary, the controller plays a vital role in the overall performance of a servo motor system. It enables precise motion control, utilizes feedback for closed-loop control, implements PID control algorithms, plans complex trajectories, monitors system parameters, and facilitates communication and integration. The controller’s capabilities and effectiveness directly impact the motor’s performance in terms of accuracy, responsiveness, stability, and overall system efficiency.

How is the size of a servo motor determined based on application requirements?

The size of a servo motor is an important consideration when selecting a motor for a specific application. The size of the motor is determined based on various factors related to the application requirements. Let’s explore how the size of a servo motor is determined:

1. Torque Requirements:

One of the primary factors in determining the size of a servo motor is the torque requirements of the application. The motor should be able to generate sufficient torque to handle the load and overcome any resistance or friction in the system. The required torque depends on factors such as the weight of the load, the distance from the motor’s axis of rotation, and any additional forces acting on the system. By analyzing the torque requirements, one can select a servo motor with an appropriate size and torque rating to meet the application’s needs.

2. Speed and Acceleration Requirements:

The desired speed and acceleration capabilities of the application also influence the size of the servo motor. Different applications have varying speed and acceleration requirements, and the motor needs to be capable of achieving the desired performance. Higher speeds and accelerations may require larger motors with more powerful components to handle the increased forces and stresses. By considering the required speed and acceleration, one can determine the size of the motor that can meet these demands.

3. Inertia and Load Inertia Ratio:

The inertia of the load and the inertia ratio between the load and the servo motor are important considerations in sizing the motor. Inertia refers to the resistance of an object to changes in its rotational motion. If the load has a high inertia, it requires a servo motor with sufficient size and torque to accelerate and decelerate the load effectively. The inertia ratio, which is the ratio of the load inertia to the motor inertia, affects the motor’s ability to control the load’s motion accurately. A proper balance between the load and motor inertia is necessary to achieve optimal performance and stability in the system.

4. Duty Cycle and Continuous Operation:

The duty cycle and continuous operation requirements of the application also impact the motor size selection. Duty cycle refers to the ratio of the motor’s operating time to the total cycle time. Applications with high-duty cycles or continuous operation may require larger motors that can handle sustained operation without overheating or performance degradation. It is important to consider the motor’s continuous torque rating and thermal characteristics to ensure it can operate reliably under the given duty cycle requirements.

5. Physical Space Constraints:

The physical space available for installing the servo motor is another factor to consider. The motor’s dimensions should fit within the available space, considering factors such as motor length, diameter, and any mounting requirements. It is essential to ensure that the chosen motor can be easily integrated into the system without interfering with other components or causing space constraints.

6. Weight Limitations:

The weight limitations of the application may influence the motor size selection. If there are weight restrictions, such as in mobile or lightweight applications, it is necessary to choose a servo motor that is compact and lightweight while still providing the required performance. Lighter servo motors can help optimize the overall weight and balance of the system.

7. Cost Considerations:

Cost is also a factor to consider when determining the size of a servo motor. Larger motors with higher torque and performance capabilities tend to be more expensive. It is important to strike a balance between the required performance and the cost constraints of the application. Analyzing the cost-effectiveness and overall value of the motor in relation to the application requirements is essential.

By considering these factors, one can determine the appropriate size of a servo motor that can meet the specific application requirements. It is advisable to consult with manufacturers or experts in the field to ensure the chosen motor size aligns with the application needs and provides optimal performance and reliability.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-01-16

China factory Kc180-M23020 (Z) AC Synchronous Servo Three Phase Electric Motor for Machine Tools vacuum pump distributors

Product Description

Product Description

KND brand was founded in ZheJiang in 1993, mainly engaged in CNC system and industrial automation product research and development, production, sales and service. After nearly 30 years of development, KND has a series of products in 6 categories, including CNC system, robot controller, pan-automation controller, feed drive and motor, spindle drive and motor, and industrial Internet, which meet the application needs of CNC lathes, CNC milling machines, machining centers, grinding machines and other tool and equipment industries and industrial robots, truss robots, workshop networking, data acquisition and analysis, etc., providing a sufficient range of choices for different users.

>·Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

>·Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

>·On Your Need

We can modify standard products or customize them to meet your specific needs.

- Motor Features

- Five pairs of poles, smaller volume (80% of the volume of the original 4 pairs of poles ST series motor)

- Equipped with high resolution encoder (23-bit absolute encoder)

- Maximum torque 300%, stronger overload capacity

- The protection level is increased to IP67

- The vibration level is raised to A level

- Motor heating is reduced by 20%

- 380V motor, rated speed improved

Model Explanation

Wiring

Power Socket

4-core:Sockets of KA180/ KC180/KD180 series are universal

| Winding | U | V | W | PE |

| Core No. | A | B | C | D |

23/25-bit Absolute Encoder Socket

7-core: applicable for KA110/KA130/KD130/KA180/KD180 serie

| Signal | 5V | SD+ | 0V | SD- | E+ | E- | FG |

| Core No. | 7 | 6 | 5 | 4 | 3 | 2 | 1 |

Power off Brake Socket

2-core: socket of 110/130/180 series are universa

| Signal | DC24V(Non-polar) | |

| Core No. | 1 | 2 |

Parameters of Motor Equipped with Power-off Brake

| Frame NO. | Rated torque | Rated voltage | Rated current | Rated power | Increased weight |

| 180 Series | 55 Nm | DC24V | 1.29A±10% | 31.0W | 4.0Kg |

Specification & Dimension

Fig.KC180 series servo motors’ mounting dimensions(unit:mm)

| Model | KC180 | KC180 | KC180 | KC180 | KC180 | |

| M18620Z | M23571Z | M28420Z | M35015Z | M48015Z | ||

| Rated power (kW) | 3.9 | 4.8 | 5.9 | 5.5 | 7.5 | |

| Rated torque (N.m) | 18.6 | 23 | 28.4 | 35 | 48 | |

| Maximum instantaneous torque (N.m) | 55.8 | 69 | 85.2 | 105 | 144 | |

| Rated speed (rpm) | 2000 | 2000 | 2000 | 1500 | 1500 | |

| Maximum speed (rpm) | 4000 | 3000 | 3000 | 3000 | 3000 | |

| Rated current (A) | 9.5 | 12.5 | 13.5 | 11.7 | 17.5 | |

| Maximum instantaneous current (A) | 28.5 | 37.5 | 40.5 | 35.1 | 52.5 | |

| Rotor inertia (kg*cm^2) | 54.19 | 66.81 | 76.08 | 105.52 | 145.18 | |

| Weight(Kg) | 19.5 | 21.7 | 23.4 | 28.7 | 35.7 | |

| Pole pairs | 5 | |||||

| Adapted driver work voltage (VAC) | 380 | |||||

| Insulation class | F | |||||

| Protection level | IP67 | |||||

| Installation type | Flange mounting | |||||

| Environment | Temperature | -15~40ºC (no freezing) ,Storage temperature: -15~70ºC (no freezing) | ||||

| Humidity | 80%RH below (no condensation) ,Storage humidity: 90%RH below (no condensation) | |||||

| Air | Indoor (no direct sunlight), no corrosive and flammable gas, no oil mist and dust | |||||

| Vibration | Vibration speed below 0.5mm/s | |||||

| LL | With brake | 226 | 241 | 251 | 286 | 331 |

*Note: We can manufacture products according to customer’s requirements.

Motor characteristic curve

A:Continuous work area;B:Short-term work area

Company Profile

ZheJiang KND Automation Technology CO.,Ltd

ABOUT US

ZheJiang KND CNC Technique Co.LTD(KND) was established in 1993.It is a joint-stock private enterprise that is the earliest 1 focusing on the research,production,sales and service of CNC system in China.It has the qualification of national high-tech enterprise,and it is 1 of the largest CNC system brand in China.

KND has the core technology of self-research and possesses independent intellectual property rights. After 30 years’ development, it has a number of series products: CNC system, robot controller, automation controller, feed driver and motor, spindle driver and motor, industrial Internet.These products can meet the application requirements of CNC lathes, CNC milling machines, machining centers,grinding machines and other industrial equipments.It can also be used in industrial robots, truss robots, workshop networking,data collection and analysis,and other automation fields.So,KND provided a full range of choices for different kinds of clients.

DEVELOPMENT HISTORY

PRODUCT DISTRIBUTION

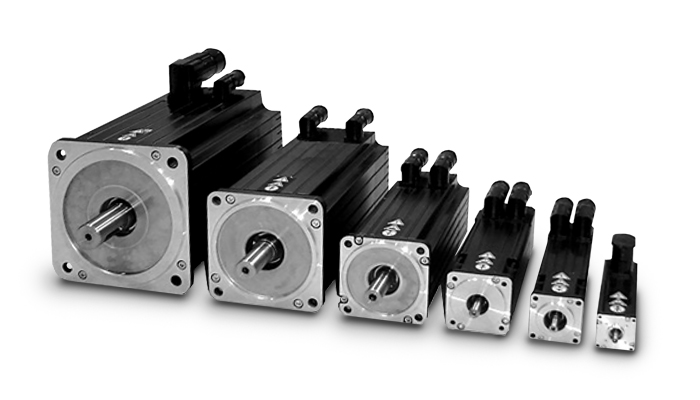

MOTOR OVERVIEW

K series synchronous servo motor is a high-performance five-pole motor developed by KND;its power ranges from 0.2kW to 7.5kW and its frame includes 60, 80, 90, 110,130, 180 series. The kind of products have the characteristics of small size, high power, high speed, better encoder configuration, and strong overload capacity.If it is used with the SD510 series driver of KND, it can make the position control come true quickly and accurately.This combination can be applied in a variety of occasions which have a higher requirements for precision control.

ZJY (-K) series AC spindle servo motor used for CNC machine tools has the characteristics of compact structure,long service life,small moment of inertia and higher control accuracy. Combined with ZD210 series of new spindle servo driver, can make its performance get better display.It can be widely used in various CNC machine tools and it can also be the spindle,feed and other parts of the CNC mechanical products.

K series synchronous servo motor is a high-performance five-pole motor developed by KND;its power ranges from 0.2kW to 7.5kW and its frame includes 60, 80, 90, 110,130, 180 series. The kind of products have the characteristics of small size, high power, high speed, better encoder configuration, and strong overload capacity.If it is used with the SD510 series driver of KND, it can make the position control come true quickly and accurately.This combination can be applied in a variety of occasions which have a higher requirements for precision control.

EXHIBITIONS

CERTIFICATE PATENT DISPLAY

FAQ

Payments

1) We can accept EXW, FOB

2) Payment must be made before shipment.

3) Import duties, taxes and charges are not included in the item price or shipping charges. These charges are the buyer’s responsibility.

Shipping

1) We only ship to your confirmed address. Please make sure your shipping address is correct before purchase.

2) Most orders will be shipped out within 3-7 working days CHINAMFG payment confirmation.

3) Shipping normally takes 7-25 working days. Most of the items will delivery in 2 weeks, while there will be a delay for something we cannot control (such as the bad weather). If it happens, just contact us, we will help you check and resolve any problem.

4) Please check the package CHINAMFG receipt, if there are some damages, please contact us immediately.

Feedback & Refund

1) Feedback is important to us, if you have any problem with our products, please contact us, our technician will give you useful advises.

2) When you have the parcel and not satisfied with the goods or it is other problem, please tell us immediately, and provide us a photo showing the detail.

3) Any reason requiring for all refund. Items must be in original condition and no physical damage. Buyer responsible for all shipping cost.

If you need more information, please contact with us. We will attach great importance to your any problems.Hope we could establish a long-term effective cooperation.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial |

|---|---|

| Operating Speed: | Constant Speed |

| Operation Mode: | Electric Motor |

| Magnetic Structure: | Permanent Magnet |

| Function: | Driving |

| Structure: | Rotating Pole Type (Armature Fixed) |

Are there common issues or challenges associated with servo motor systems, and how can they be addressed?

Servo motor systems are widely used in various applications, but they can encounter common issues or challenges that affect their performance and reliability. Let’s explore some of these issues and discuss potential solutions:

1. Positioning and Tracking Errors:

One common challenge in servo motor systems is positioning and tracking errors. These errors can occur due to factors such as mechanical backlash, encoder resolution limitations, or disturbances in the system. To address this issue, careful calibration and tuning of the servo control system are necessary. This includes adjusting feedback gains, implementing feedback filtering techniques, and utilizing advanced control algorithms to improve the system’s accuracy and minimize errors. Additionally, employing high-resolution encoders and backlash compensation mechanisms can help enhance the positioning and tracking performance.

2. Vibration and Resonance:

Vibration and resonance can impact the performance of servo motor systems, leading to reduced accuracy and stability. These issues can arise from mechanical resonances within the system or external disturbances. To mitigate vibration and resonance problems, it is crucial to analyze the system’s dynamics and identify critical resonant frequencies. Implementing vibration dampening techniques such as mechanical isolation, using vibration-absorbing materials, or employing active vibration control methods can help minimize the effect of vibrations and improve the system’s performance.

3. Overheating and Thermal Management:

Servo motors can generate heat during operation, and inadequate thermal management can lead to overheating and potential performance degradation. To address this issue, proper cooling and thermal management techniques should be employed. This may involve using heat sinks, fans, or liquid cooling systems to dissipate heat efficiently. Ensuring adequate ventilation and airflow around the motor and avoiding excessive current or overloading can also help prevent overheating. Monitoring the motor’s temperature and implementing temperature protection mechanisms can further safeguard the motor from thermal damage.

4. Electrical Noise and Interference:

Electrical noise and interference can affect the performance and reliability of servo motor systems. These issues can arise from electromagnetic interference (EMI) or radio frequency interference (RFI) from nearby equipment or electrical sources. To mitigate electrical noise, proper shielding and grounding techniques should be employed. Using shielded cables, ferrite cores, and grounding the motor and control system can help minimize the impact of noise and interference. Additionally, employing filtering techniques and surge protection devices can further improve system robustness against electrical disturbances.

5. System Integration and Compatibility:

Integrating a servo motor system into a larger control system or automation setup can present challenges in terms of compatibility and communication. Ensuring proper compatibility between the servo motor and the control system is crucial. This involves selecting appropriate communication protocols, such as EtherCAT or Modbus, and ensuring compatibility with the control signals and interfaces. Employing standardized communication interfaces and protocols can facilitate seamless integration and interoperability. Additionally, thorough testing and verification of the system’s compatibility before deployment can help identify and address any integration issues.

6. Maintenance and Service:

Maintenance and service requirements are important considerations for servo motor systems. Regular maintenance, including lubrication, inspection, and cleaning, can help prevent issues related to wear and tear. Following manufacturer-recommended maintenance schedules and procedures is essential to ensure the longevity and optimal performance of the motor. In case of any malfunctions or failures, having access to technical support from the manufacturer or trained service personnel can help diagnose and address problems effectively.

By being aware of these common issues and challenges associated with servo motor systems and implementing appropriate solutions, it is possible to enhance the performance, reliability, and lifespan of the servo motor system. Regular monitoring, proactive maintenance, and continuous improvement can contribute to optimizing the overall operation and efficiency of the system.

Are there different types of servo motors, and how do they differ?

Yes, there are different types of servo motors available, each with its own characteristics and applications. The variations among servo motors can be attributed to factors such as construction, control mechanisms, power requirements, and performance specifications. Let’s explore some of the common types of servo motors and how they differ:

1. DC Servo Motors:

DC servo motors are widely used in various applications. They consist of a DC motor combined with a feedback control system. The control system typically includes a position or velocity feedback sensor, such as an encoder or a resolver. DC servo motors offer good speed and torque control and are often employed in robotics, automation, and hobbyist projects. They can be operated with a separate motor driver or integrated into servo motor units with built-in control electronics.

2. AC Servo Motors:

AC servo motors are designed for high-performance applications that require precise control and fast response times. They are typically three-phase motors and are driven by sinusoidal AC waveforms. AC servo motors often incorporate advanced control algorithms and feedback systems to achieve accurate position, velocity, and torque control. These motors are commonly used in industrial automation, CNC machines, robotics, and other applications that demand high precision and dynamic performance.

3. Brushed Servo Motors:

Brushed servo motors feature a traditional brushed DC motor design. They consist of a rotor with a commutator and carbon brushes that make physical contact with the commutator. The brushes provide electrical connections, allowing the motor’s magnetic field to interact with the rotor’s windings. Brushed servo motors are known for their simplicity and cost-effectiveness. However, they may require more maintenance due to brush wear, and they generally have lower efficiency and shorter lifespan compared to brushless servo motors.

4. Brushless Servo Motors:

Brushless servo motors, also known as brushless DC (BLDC) motors, offer several advantages over brushed motors. They eliminate the need for brushes and commutators, resulting in improved reliability, higher efficiency, and longer lifespan. Brushless servo motors rely on electronic commutation, typically using Hall effect sensors or encoder feedback for accurate rotor position detection. These motors are widely used in robotics, industrial automation, aerospace, and other applications that require high-performance motion control with minimal maintenance.

5. Linear Servo Motors:

Linear servo motors are designed to provide linear motion instead of rotational motion. They consist of a primary part (stator) and a secondary part (slider or forcer) that interact magnetically to generate linear motion. Linear servo motors offer advantages such as high speed, high acceleration, and precise positioning along a linear axis. They find applications in various industries, including semiconductor manufacturing, packaging, printing, and machine tools.

6. Micro Servo Motors:

Micro servo motors are small-sized servo motors often used in applications with limited space and low power requirements. They are commonly found in hobbyist projects, model airplanes, remote-controlled vehicles, and small robotic systems. Micro servo motors are lightweight, compact, and offer reasonable precision and control for their size.

These are some of the different types of servo motors available, each catering to specific applications and requirements. The choice of servo motor type depends on factors such as the desired performance, accuracy, power requirements, environmental conditions, and cost considerations. Understanding the differences between servo motor types is essential for selecting the most suitable motor for a particular application.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-01-16

China Good quality Factory Wholesale Servo Brushless Motor for Smart Sanitary Machine with Great quality

Product Description

AC Servo Motor for Injection Machine

Mechanical dimensions

ABOUT US

Ritscher group was established in 2006.we always focus on micro-motors for household and industrial electrical appliance.Currently, we have professional micro-motor factories separatlly located in ZheJiang & ZHangZhoug province.It has 50,000 square CHINAMFG plants and more than 500 employees, annual output is 5 million pcs and has 10 million pcs annual producing capacity.After years development,we built a great reputation in the domestic and oversea market and have the trust from our global customers.

We started our business from shaded pole motors, after 10 years development,our products is enlarged to BLDC motors ,capacitor motors ,synchronous motors,stepping motors,servo motors, and PMDC motors.Our products are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments.

To design the lastest technology motors and meet our customers requirments,we have the very capable R&D team,to ensure our products quality ,we have very strict manage system for our production department & QC department,to make our cost lower,we have the very professional purchase department, We dedicate to make every details better than we could do.

To offer quick and better service to our customers in Australia and New Zeland,we set up branch office in Australia since 2017 with exprienced consultant to support the business ,which will bring more customers to get know of us.

We will keep doing our job,move CHINAMFG step by step to make our business area wider and brighter.

Our company FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,Hair Dryer Motor Blender Motor Mixer Motor,

Shade Pole Motor,Capacitor Motor,BLDC Motor PMDC Motor,Synchronous Motor,Stepping Motor etc.

(2) Q: Is it possible to visit your factory

A: Sure. But please kindly keep us posted a few days in advance. We need to check our

schedule to see if we are available then.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will

be difficult for us to provide, because all of our motors are custom made and no stock

available if there is no further needs. If just sample testing before the official order and

our MOQ, price and other terms are acceptable, we’d love to provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it’s also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement. But the less the better (like no more than 5pcs) on condition that the quantity is enough in case any changes needed after initial testing.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal |

|---|---|

| Speed: | Constant Speed |

| Number of Stator: | Single-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Number of Poles: | 2 |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the cost of servo motors vary based on their specifications and features?

The cost of servo motors can vary significantly based on their specifications and features. Several factors influence the price of servo motors, and understanding these factors can help in selecting the most cost-effective option for a specific application. Let’s explore in detail how the cost of servo motors can vary:

1. Power Rating:

One of the primary factors affecting the cost of a servo motor is its power rating, which is typically measured in watts or kilowatts. Higher power-rated servo motors generally cost more than lower-rated ones due to the increased materials and manufacturing required to handle higher power levels. The power rating of a servo motor is determined by the torque and speed requirements of the application. Higher torque and speed capabilities often correspond to higher costs.

2. Torque and Speed:

The torque and speed capabilities of a servo motor directly impact its cost. Servo motors designed for high torque and high-speed applications tend to be more expensive due to the need for robust construction, specialized materials, and advanced control electronics. Motors with higher torque and speed ratings often require more powerful magnets, larger windings, and higher precision components, contributing to the increase in cost.

3. Frame Size:

The physical size or frame size of a servo motor also plays a role in determining its cost. Servo motors come in various frame sizes, such as NEMA (National Electrical Manufacturers Association) standard sizes in North America. Larger frame sizes generally command higher prices due to the increased materials and manufacturing complexity required to build larger motors. Smaller frame sizes, on the other hand, may be more cost-effective but may have limitations in terms of torque and speed capabilities.

4. Feedback Mechanism:

The feedback mechanism used in a servo motor affects its cost. Servo motors typically employ encoders or resolvers to provide feedback on the rotor position. Higher-resolution encoders or more advanced feedback technologies can increase the cost of the motor. For example, servo motors with absolute encoders, which provide position information even after power loss, tend to be more expensive than those with incremental encoders.

5. Control Features and Technology:

The control features and technology incorporated into a servo motor can influence its cost. Advanced servo motors may offer features such as built-in controllers, fieldbus communication interfaces, advanced motion control algorithms, or integrated safety functions. These additional features contribute to the cost of the motor but can provide added value and convenience in certain applications. Standard servo motors with basic control functionality may be more cost-effective for simpler applications.

6. Brand and Reputation:

The brand and reputation of the servo motor manufacturer can impact its cost. Established and reputable brands often command higher prices due to factors such as quality assurance, reliability, technical support, and extensive product warranties. While motors from less-known or generic brands may be more affordable, they may not offer the same level of performance, reliability, or long-term support.

7. Customization and Application-Specific Requirements:

If a servo motor needs to meet specific customization or application-specific requirements, such as specialized mounting options, environmental sealing, or compliance with industry standards, the cost may increase. Customization often involves additional engineering, design, and manufacturing efforts, which can lead to higher prices compared to off-the-shelf servo motors.

It’s important to note that the cost of a servo motor is not the sole indicator of its quality or suitability for a particular application. It is essential to carefully evaluate the motor’s specifications, features, and performance characteristics in relation to the application requirements to make an informed decision.

In summary, the cost of servo motors varies based on factors such as power rating, torque and speed capabilities, frame size, feedback mechanism, control features and technology, brand reputation, and customization requirements. By considering these factors and comparing different options, it is possible to select a servo motor that strikes the right balance between performance and cost-effectiveness for a specific application.

What is the significance of closed-loop control in servo motor operation?

Closed-loop control plays a significant role in the operation of servo motors. It involves continuously monitoring and adjusting the motor’s behavior based on feedback from sensors. The significance of closed-loop control in servo motor operation can be understood through the following points:

1. Accuracy and Precision:

Closed-loop control allows servo motors to achieve high levels of accuracy and precision in positioning and motion control. The feedback sensors, such as encoders or resolvers, provide real-time information about the motor’s actual position. This feedback is compared with the desired position, and any deviations are used to adjust the motor’s behavior. By continuously correcting for errors, closed-loop control ensures that the motor accurately reaches and maintains the desired position, resulting in precise control over the motor’s movements.

2. Stability and Repeatability:

Closed-loop control enhances the stability and repeatability of servo motor operation. The feedback information enables the control system to make continuous adjustments to the motor’s inputs, such as voltage or current, in order to minimize position errors. This corrective action helps stabilize the motor’s behavior, reducing oscillations and overshoot. As a result, the motor’s movements become more consistent and repeatable, which is crucial in applications where the same motion needs to be replicated accurately multiple times.

3. Compensation for Disturbances:

One of the key advantages of closed-loop control is its ability to compensate for disturbances or variations that may occur during motor operation. External factors, such as friction, load changes, or variations in the operating environment, can affect the motor’s performance and position accuracy. By continuously monitoring the actual position, closed-loop control can detect and respond to these disturbances, making the necessary adjustments to maintain the desired position. This compensation capability ensures that the motor remains on track despite external influences, leading to more reliable and consistent operation.

4. Improved Response Time:

Closed-loop control significantly improves the response time of servo motors. The feedback sensors provide real-time information about the motor’s actual position, which allows the control system to quickly detect any deviations from the desired position. Based on this feedback, the control system can adjust the motor’s inputs promptly, allowing for rapid corrections and precise control over the motor’s movements. The fast response time of closed-loop control is crucial in applications where dynamic and agile motion control is required, such as robotics or high-speed automation processes.

5. Adaptability to Changing Conditions:

Servo motors with closed-loop control are adaptable to changing conditions. The feedback information allows the control system to dynamically adjust the motor’s behavior based on real-time changes in the operating environment or task requirements. For example, if the load on the motor changes, the control system can respond by adjusting the motor’s inputs to maintain the desired position and compensate for the new load conditions. This adaptability ensures that the motor can perform optimally under varying conditions, enhancing its versatility and applicability in different industrial settings.

In summary, closed-loop control is of significant importance in servo motor operation. It enables servo motors to achieve high levels of accuracy, stability, and repeatability in position and motion control. By continuously monitoring the motor’s actual position and making adjustments based on feedback, closed-loop control compensates for disturbances, enhances response time, and adapts to changing conditions. These capabilities make closed-loop control essential for achieving precise and reliable operation of servo motors in various industrial applications.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-01-10

China Hot selling High Performance Speed Control Servo Motor AC Servo Motor with Tamawaga Encoder and Servo Driver for Lathe Machine Parts/Drilling Machine Parts with Best Sales

Product Description

High Performance Speed Control Servo Motor AC Servo Motor With Tamawaga Encoder And Servo Driver for Lathe Machine Parts/Drilling Machine Parts

SZGH-13150CC is 1500W servo motor ,optimizing design, compact, beautiful contour, long-term continuous working in rated working mode and economic type

Packing list :

1) SZGH-13150CC 1500w servo motor -1pcs

2) SZGH-SD2026 220v servo driver – 1pcs

3) SZGH1MX-5M 5meter motor cables -1pcs

4) SZGH1EX-5M 5 meter encoder cables -1 pcs

5) Manual -1pcs

Pls tell us at first time when you need :

1) Brake motor

2) Absolutely encoder

3) long cables

4)Ethernet type

Product Description

Application:Automation Machine,Robot Arm,Braided Belt Machine,Computeriaed Flat Knitting Machine,Embroidery Machine,AGV Car,Woodworking Engeaving Machine,CNC Machine…

Product Parameters

| Power(W )Torque(N.m) Speed (rpm) | |||||

| Flange | Model | Power | Torque | Speed | Matched Servo Drive |

| 40mm | SZGH-04005D | 50 | 0.16 | 3000 | SZGH-SD2004 |

| SZGH-5711D | 100 | 0.32 | 3000 | ||

| 60mm | SZGH-06571DC | 200 | 0.6 | 3000 | |

| SZGH-06040DC | 400 | 1.3 | 3000 | ||

| SZGH-06060DC | 600 | 1.9 | 3000 | ||

| 80mm | SZGH-08040DC | 400 | 1.3 | 3000 | SZGH-SD2571 |

| SZGH-08075DC | 750 | 2.4 | 3000 | ||

| SZGH-08075BC | 750 | 3.5 | 2000 | ||

| SZGH-5710CC | 1000 | 4 | 2500 | ||

| 90mm | SZGH-09075DC | 750 | 2.4 | 3000 | |

| SZGH-09075BC | 750 | 3.5 | 2000 | ||

| SZGH-5710CC | 1000 | 4 | 2500 | ||

| 110mm | SZGH-11060DC | 600 | 2 | 3000 | SZGH-SD2026 |

| SZGH-11080DC | 800 | 4 | 2000 | ||

| SZGH11120DC | 1200 | 4 | 3000 | ||

| SZGH-11150DC | 1500 | 5 | 3000 | ||

| SZGH-11120BC | 1200 | 6 | 2000 | ||

| SZGH11180DC | 1800 | 6 | 3000 | ||

| 130mm | SZGH-13100CC | 1000 | 4 | 2500 | |

| SZGH-13130CC | 1300 | 5 | 2500 | ||

| SZGH-13150CC | 1500 | 6 | 2500 | ||

| SZGH-13200CC | 2000 | 77 | 2500 | SZGH-SD2026/ SZGH-SD4038(380V) | |

| SZGH-13100AC | 1000 | 10 | 1000 | ||

| SZGH-13150AC | 1500 | 10 | 1500 | ||

| SZGH-13230AC | 2300 | 15 | 1500 | ||

| SZGH-13260CC | 2600 | 10 | 2500 | ||

| SZGH-13380CC | 3800 | 15 | 2500 | ||

| 150mm | SZGH-15380CC | 3800 | 15 | 2500 | SZGH-4038 |

| SZGH-15300BC | 3000 | 15 | 2000 | ||

| SZGH-15360BC | 3600 | 18 | 2000 | ||

| SZGH-1S470BC | 4700 | 23 | 2000 | SZGH-4075 | |

| SZGH-15550BC | 5500 | 27 | 2000 | ||

| 180mm | SZGH-18270BC | 2700 | 17.2 | 1500 | |

| SZGH-18290BC | 2900 | 27 | 1000 | ||

| SZGH-18300CC | 3000 | 19 | 1500 | ||

| SZGH-18370BC | 3700 | 35 | 1000 | ||

| SZGH-18430AC | 4300 | 27 | 1500 | ||

| SZGH-18450CC | 4500 | 21.5 | 2000 | ||

| SZGH-18550CC | 5500 | 35 | 1500 | ||

| SZGH-18750CC | 7500 | 48 | 1500 | ||

| NOTE : The above models support 2500PPR incremental encoder | |||||

| SD Series | SD2004 | SD2571 | SD2026 | SD4038 | SD4075 |

| Output Power | 50W~600W | 400W~1kW | 600W~3. 8kW | 2kW~3 8KW | 3kW~75kW |

| Input Power | Single/Three Phase AC220V-15%~+10% | Three Phase 380V | |||

| 50/60Hz | |||||

| Control Mode | 0. Position Control: 1 Speed Control; 2: Torque Control: 3:Position/Speed Control; | ||||

| 4:PositionT orque Control: 5:SpeedTorque Control | |||||

| Protective | Over-speed/Over-voltageUnder-voltage Over-current/Overload/Encoder Error/ | ||||

| Function | Control Power Eror/ Position Offset Enor | ||||

| Monitor Function | SpeedPositionPulses /Offset/TorqueCurrent/Status. | ||||

| Digital Input | 1:Servo Enable: 2:Alam Reset: 3:CCW-Forbidden: 4:CW-Forbi dden: 5:Clear | ||||

| Position Ofiset; 6:Pulse Input Forbidden; 7:CCW Torque Limit: 8:CW Torque Limit | |||||

| Digital Output | Servo-Ready On/Alam/ Orientation EndBraker Control | ||||

| Energy Braking | Support buit in Extemal Resistor Braking | ||||

| DriveLoad | Less than 3 times of rotor inertia | ||||

| Display | 5 bits LED Indicator display: 4 Operate keys | ||||

| Communication | RS485 | ||||

| Position Control | Input Mode | 0: Pulse+Direction | |||

| 1:CCW/CW Pulse | |||||

| I . . 2: AB Phase Orthogonal Pulse | |||||

| 1 . 1 3:Inner Position Control | |||||

| Electic Ratio | Numerator of Electric Ratio: 1~32767 | ||||

| Denominator of Electric Ratio: 1~32767 | |||||

| 130mm | SZGH-13100CC/T | 1000 | 4 | 2500 | SZGH-SD2026 |

| SZGH-13130CC/T | 1300 | 5 | 2500 | SZGH-SD2026 | |

| SZGH-13150CC/T | 1500 | 6 | 2500 | SZGH-SD2026 | |

| SZGH-13200CC/T | 2000 | 77 | 2500 | SZGH-SD2026/ SZGH-SD4038(380V) | |

| SZGH-13100AC/T | 1000 | 10 | 1000 | ||

| SZGH-13150AC/T | 1500 | 10 | 1500 | ||

| SZGH-13230AC/T | 2300 | 15 | 1500 | ||

| SZGH-13260CC/T | 2600 | 10 | 2500 | ||

| SZGH-13380CC/T | 3800 | 15 | 2500 | ||

| 150mm | SZGH-15380CC/T | 3800 | 15 | 2500 | SZGH-4038 |

| SZGH-15300BC/T | 3000 | 15 | 2000 | ||

| SZGH-15360BC/T | 3600 | 18 | 2000 | ||

| SZGH-1S470BC/T | 4700 | 23 | 2000 | SZGH-4075 | |

| SZGH-15550BC/T | 5500 | 27 | 2000 | ||

| 180mm | SZGH-18270BC/T | 2700 | 17.2 | 1500 | |

| SZGH-18290BC/T | 2900 | 27 | 1000 | ||

| SZGH-18300CC/T | 3000 | 19 | 1500 | ||

| SZGH-18370BC/T | 3700 | 35 | 1000 | ||

| SZGH-18430AC/T | 4300 | 27 | 1500 | ||

| SZGH-18450CC/T | 4500 | 21.5 | 2000 | ||

| SZGH-18550CC/T | 5500 | 35 | 1500 | ||

| SZGH-18750CC/T | 7500 | 48 | 1500 | ||

| NOTE : The above models support 2500PPR incremental encoder & brake | |||||

Certifications

Packaging & Shipping

1.Industrial packing: plastic bag +foam boxes+ carton +wooden pallets

2.Commercial packing: plastic bag+ foam boxes + carton

3.As the clients requirement

Delivery Detail: Normally ready goods and stock within 2- 5days

Company Profile

HangZhou CHINAMFG Automation CO.,LTD (Formerly known as ‘HangZhou CHINAMFG Automation Co.,Limited(Built in 19 November 2571)’) is 1 of the leading CNC & automatic company in China, specialized in designing projects, marketing, and oversea trading, having extensive experience in CNC package solution, Our focus has been on providing the high quality of Industrial robot arm Lathe CNC system, Milling CNC system, Engraving CNC system, Grinding & router CNC system, Motor & driver, Spindle servo motor & driver, Gear reducer.

SZGH’ products have been in working with a wide variety of CNC machinery and automatic processing equipment with high performance and good precision, stably. We have now established a reliable structure , our experienced engineers and technicians are able to provide professional consultancy and offer you most suitable CNC application solution.

Our strict quality control measures guarantee excellent reliability and high standard of quality. Utilizing advanced CNC machinery to test every product, 100 percent inspection is made before packaging and shipment. Moreover, We also offer flexible lead times to support your business.

We have a large number of customers across Asia, America, the Middle East, Europe, South America, and Africa. Specially we already built own business corporate group in Middle East market.

Our Advantages

Why Choose Us ?

1:more than 10 years development and production, we are manufacturer

2:12-24 month warranty

3: more than 40 patents

4:Free training and easy operation

5: We can response 24 hours as you need

After Sales Service

Best & Professional after- sales supports

Our company have very professional engineers teams ;

We can provide the professional after -sales service to our all clients ;

Here is our engineer Mike solved the problems for our customer ;

Best supports !! Quicly reply !!

Buy at ease , use at ease !!!

FAQ

Q: Do you support CNC system and Robotic Arm System customized manufacturing?

A: Yes,we can customized manufacturing according to customer’s requirment. We support to OEM your own company display interface

and logo.

Q: How long is your CNC System and Robotic Arm System delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to

quantity.10-20 days if customized manufacturing.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample with sample price.

Q: What is your terms of payment ?

A: Payment=1000USD, 70% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machine Tool |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Explosion-Proof Type |

| Number of Poles: | 4 |

| Customization: |

Available

|

|

|---|

Are there advancements or trends in servo motor technology that users should be aware of?

Yes, there have been significant advancements and emerging trends in servo motor technology that users should be aware of. These developments aim to enhance performance, improve efficiency, and provide new capabilities. Here are some noteworthy advancements and trends in servo motor technology:

1. Higher Power Density:

Advancements in servo motor design and manufacturing techniques have led to higher power densities. This means that modern servo motors can deliver more power in a smaller and lighter package. Higher power density allows for more compact and efficient machine designs, particularly in applications with limited space or weight restrictions.

2. Improved Efficiency:

Efficiency is a crucial aspect of servo motor technology. Manufacturers are continuously striving to improve motor efficiency to minimize energy consumption and reduce operating costs. Advanced motor designs, optimized winding configurations, and the use of high-quality materials contribute to higher efficiency levels, resulting in energy savings and lower heat generation.

3. Integration of Electronics and Control:

Integration of electronics and control functions directly into servo motors is becoming increasingly common. This trend eliminates the need for external motor controllers or drives, simplifies wiring and installation, and reduces overall system complexity. Integrated servo motors often include features such as on-board motion control, communication interfaces, and safety features.

4. Digitalization and Connectivity:

Servo motor technology is embracing digitalization and connectivity trends. Many modern servo motors come equipped with digital interfaces, such as Ethernet or fieldbus protocols, enabling seamless integration with industrial communication networks. This connectivity allows for real-time monitoring, diagnostics, and remote control of servo motors, facilitating condition monitoring, predictive maintenance, and system optimization.

5. Advanced Feedback Systems:

Feedback systems play a critical role in servo motor performance. Recent advancements in feedback technology have resulted in more accurate and higher-resolution encoders, resolvers, and sensors. These advanced feedback systems provide precise position and velocity information, enabling improved motion control, better accuracy, and enhanced dynamic response in servo motor applications.

6. Smart and Adaptive Control Algorithms:

Servo motor control algorithms have evolved to include smart and adaptive features. These algorithms can adapt to changing load conditions, compensate for disturbances, and optimize motor performance based on real-time feedback. Smart control algorithms contribute to smoother operation, increased stability, and improved tracking accuracy in various applications.

7. Safety and Functional Safety:

Safety is a paramount concern in industrial automation. Servo motor technology has incorporated safety features and functional safety standards to ensure the protection of personnel and equipment. Safety-rated servo motors often include features such as safe torque off (STO) functionality, safe motion control, and compliance with safety standards like ISO 13849 and IEC 61508.

It’s important for users to stay informed about these advancements and trends in servo motor technology. By understanding the latest developments, users can make informed decisions when selecting and implementing servo motors, leading to improved performance, efficiency, and reliability in their applications.

Are there different types of servo motors, and how do they differ?

Yes, there are different types of servo motors available, each with its own characteristics and applications. The variations among servo motors can be attributed to factors such as construction, control mechanisms, power requirements, and performance specifications. Let’s explore some of the common types of servo motors and how they differ:

1. DC Servo Motors:

DC servo motors are widely used in various applications. They consist of a DC motor combined with a feedback control system. The control system typically includes a position or velocity feedback sensor, such as an encoder or a resolver. DC servo motors offer good speed and torque control and are often employed in robotics, automation, and hobbyist projects. They can be operated with a separate motor driver or integrated into servo motor units with built-in control electronics.

2. AC Servo Motors:

AC servo motors are designed for high-performance applications that require precise control and fast response times. They are typically three-phase motors and are driven by sinusoidal AC waveforms. AC servo motors often incorporate advanced control algorithms and feedback systems to achieve accurate position, velocity, and torque control. These motors are commonly used in industrial automation, CNC machines, robotics, and other applications that demand high precision and dynamic performance.

3. Brushed Servo Motors:

Brushed servo motors feature a traditional brushed DC motor design. They consist of a rotor with a commutator and carbon brushes that make physical contact with the commutator. The brushes provide electrical connections, allowing the motor’s magnetic field to interact with the rotor’s windings. Brushed servo motors are known for their simplicity and cost-effectiveness. However, they may require more maintenance due to brush wear, and they generally have lower efficiency and shorter lifespan compared to brushless servo motors.

4. Brushless Servo Motors:

Brushless servo motors, also known as brushless DC (BLDC) motors, offer several advantages over brushed motors. They eliminate the need for brushes and commutators, resulting in improved reliability, higher efficiency, and longer lifespan. Brushless servo motors rely on electronic commutation, typically using Hall effect sensors or encoder feedback for accurate rotor position detection. These motors are widely used in robotics, industrial automation, aerospace, and other applications that require high-performance motion control with minimal maintenance.

5. Linear Servo Motors:

Linear servo motors are designed to provide linear motion instead of rotational motion. They consist of a primary part (stator) and a secondary part (slider or forcer) that interact magnetically to generate linear motion. Linear servo motors offer advantages such as high speed, high acceleration, and precise positioning along a linear axis. They find applications in various industries, including semiconductor manufacturing, packaging, printing, and machine tools.

6. Micro Servo Motors:

Micro servo motors are small-sized servo motors often used in applications with limited space and low power requirements. They are commonly found in hobbyist projects, model airplanes, remote-controlled vehicles, and small robotic systems. Micro servo motors are lightweight, compact, and offer reasonable precision and control for their size.

These are some of the different types of servo motors available, each catering to specific applications and requirements. The choice of servo motor type depends on factors such as the desired performance, accuracy, power requirements, environmental conditions, and cost considerations. Understanding the differences between servo motor types is essential for selecting the most suitable motor for a particular application.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2023-12-29

China best Knd Kc80-M03530m8a AC Synchronous Servo Three Phase Electric Motor for Machine Tools vacuum pump oil

Product Description

Product Description

- Motor Features

- Five pairs of poles, smaller volume (80% of the volume of the original 4 pairs of poles ST series motor)

- Equipped with high resolution encoder (23-bit absolute encoder)

- Maximum torque 300%, stronger overload capacity

- The protection level is increased to IP67

- The vibration level is raised to A level

- Motor heating is reduced by 20%

- 380V motor, rated speed improved

Model Explanation

Wiring

Parameters of Motor Equipped with Power-off Brake

| Frame NO. | Rated torque | Rated voltage | Rated current | Rated power | Increased weight |

| 80 Series | 3.3 Nm | DC24V | 0.48A±10% | 11.5W | 0.8Kg |

Specification & Dimension

| Model | KC80 | KC80 | |

| M57130 | M5710 | ||

| Rated power (kW) | 0.75 | 1.0 | |

| Rated torque (N.m) | 2.5 | 3.5 | |

| Maximum instantaneous torque (N.m) | 7.5 | 10.5 | |

| Rated speed (rpm) | 3000 | 3000 | |

| Maximum speed (rpm) | 6000 | 6000 | |

| Rated current (A) | 4.8 | 5 | |

| Maximum instantaneous current (A) | 14.4 | 15 | |

| Rotor inertia (kg*cm^2) | 1.88 | 2.44 | |

| Weight(Kg)(Without brake) | 2.8 | 3.3 | |

| Pole pairs | 5 | ||

| Adapted driver work voltage (VAC) | 220 | ||

| Insulation class | F | ||

| Protection level | IP67 | ||

| Installation type | Flange mounting | ||

| Environment | Temperature | -15~40ºC (no freezing) ,Storage temperature: -15~70ºC (no freezing) | |

| Humidity | 80%RH below (no condensation) ,Storage humidity: 90%RH below (no condensation) | ||

| Air | Indoor (no direct sunlight), no corrosive and flammable gas, no oil mist and dust | ||

| Vibration | Vibration speed below 0.5mm/s | ||

| LL | Without brake | 139 | 154 |

| With brake | 179 | 194 | |

*Note: We can manufacture products according to customer’s requirements.

Motor characteristic curve

A:Continuous work area;B:Short-term work area

Company Profile

ZheJiang KND Automation Technology CO.,Ltd

ABOUT US

ZheJiang KND CNC Technique Co.LTD(KND) was established in 1993.It is a joint-stock private enterprise that is the earliest 1 focusing on the research,production,sales and service of CNC system in China.It has the qualification of national high-tech enterprise,and it is 1 of the largest CNC system brand in China.

KND has the core technology of self-research and possesses independent intellectual property rights. After 30 years’ development, it has a number of series products: CNC system, robot controller, automation controller, feed driver and motor, spindle driver and motor, industrial Internet.These products can meet the application requirements of CNC lathes, CNC milling machines, machining centers,grinding machines and other industrial equipments.It can also be used in industrial robots, truss robots, workshop networking,data collection and analysis,and other automation fields.So,KND provided a full range of choices for different kinds of clients.

DEVELOPMENT HISTORY

PRODUCT DISTRIBUTION

MOTOR OVERVIEW

K series synchronous servo motor is a high-performance five-pole motor developed by KND;its power ranges from 0.2kW to 7.5kW and its frame includes 60, 80, 90, 110,130, 180 series. The kind of products have the characteristics of small size, high power, high speed, better encoder configuration, and strong overload capacity.If it is used with the SD510 series driver of KND, it can make the position control come true quickly and accurately.This combination can be applied in a variety of occasions which have a higher requirements for precision control.

ZJY (-K) series AC spindle servo motor used for CNC machine tools has the characteristics of compact structure,long service life,small moment of inertia and higher control accuracy. Combined with ZD210 series of new spindle servo driver, can make its performance get better display.It can be widely used in various CNC machine tools and it can also be the spindle,feed and other parts of the CNC mechanical products.

ZJY (-K) series spindle servo motor’s parameters showed below, rated power: range from 3.7kW to 37kW, rated voltage: 380V, rated frequency: 25, 33.3, 50, 66.67, 83.33Hz, rated speed: 750, 1000, 1500,2000, 2500r/ min.The maximum speed can reach 12000r/ min. The working system of the motor is S1, the protection level is IP54, and the insulation level is F. There are thermal element in the interior of motors., this kind of moter lose heat by a independent fan.You can choose a motor with a photoelectric encoder or a rotary transformer,that depends on your needs.

EXHIBITIONS

CERTIFICATE PATENT DISPLAY

FAQ

Payments

1) We can accept EXW, FOB

2) Payment must be made before shipment.

3) Import duties, taxes and charges are not included in the item price or shipping charges. These charges are the buyer’s responsibility.

Shipping

1) We only ship to your confirmed address. Please make sure your shipping address is correct before purchase.

2) Most orders will be shipped out within 3-7 working days CHINAMFG payment confirmation.

3) Shipping normally takes 7-25 working days. Most of the items will delivery in 2 weeks, while there will be a delay for something we cannot control (such as the bad weather). If it happens, just contact us, we will help you check and resolve any problem.

3) Please check the package CHINAMFG receipt, if there are some damages, please contact us immediately.

Feedback & Refund

1) Feedback is important to us, if you have any problem with our products, please contact us, our technician will give you useful advises.

2) When you have the parcel and not satisfied with the goods or it is other problem, please tell us immediately, and provide us a photo showing the detail.

3) Any reason requiring for all refund. Items must be in original condition and no physical damage. Buyer responsible for all shipping cost.

If you need more information, please contact with us. We will attach great importance to your any problems.

Hope we could establish a long-term effective cooperation.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial |

|---|---|

| Operating Speed: | Constant Speed |

| Operation Mode: | Electric Motor |

| Magnetic Structure: | Permanent Magnet |

| Function: | Driving |

| Structure: | Rotating Pole Type (Armature Fixed) |

How are servo motors used in CNC machines and other precision machining equipment?