Product Description

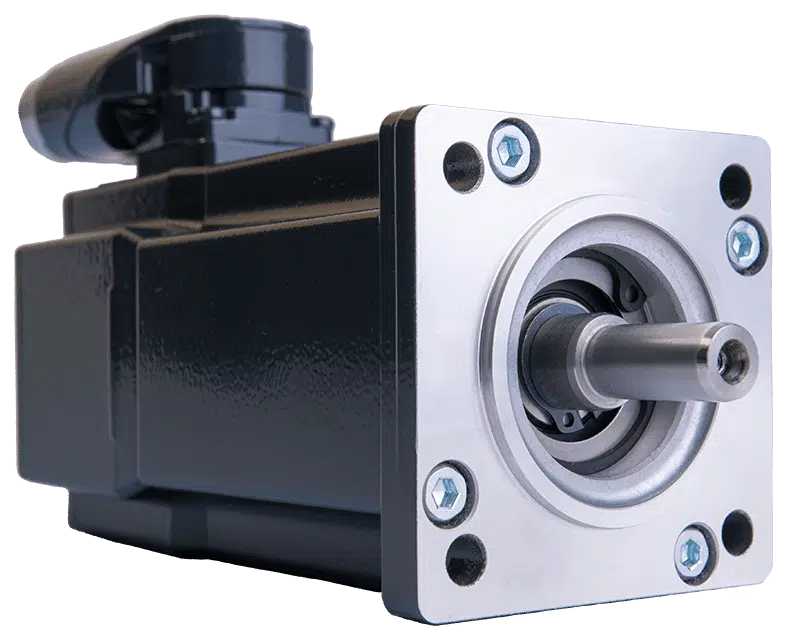

New products Micro DC servo motor for automatic control system

Product description

1.The micro DC servo motors are widely used in automatic control system as an executive component, and also can be used as a driving component.

2.This series of motors is a new series of products designed by our country, with small volume, light weight, high force index, and a high degree of product serialization, and strong generalization of parts.

Technical data

| Model | Torque N.m |

Speed r/min |

Power W |

Voltage V |

Current Not greater than A |

CW/CWW Speed Difference r/min |

||

| Armature | Excitation | Armature | Excitation | |||||

| GS70SZ01 | 127 | 3000 | 40.0 | 24 | 24 | 3.00 | 0.500 | 200 |

| GS70SZ02 | 127 | 3000 | 40.0 | 27 | 27 | 2.60 | 0.440 | 200 |

| GS70SZ03 | 127 | 3000 | 40.0 | 48 | 48 | 1.60 | 0.250 | 200 |

| GS70SZ04 | 127 | 3000 | 40.0 | 110 | 110 | 0.60 | 0.110 | 200 |

| GS70SZ05 | 108 | 6000 | 68.0 | 24 | 24 | 4.80 | 0.500 | 300 |

| GS70SZ06 | 108 | 6000 | 68.0 | 27 | 27 | 4.40 | 0.440 | 300 |

| GS70SZ06/H1 | 108 | 6000 | 68.0 | 27 | 27 | 4.40 | 0.440 | 300 |

| GS70SZ07 | 108 | 6000 | 68.0 | 48 | 48 | 2.40 | 0.250 | 300 |

| GS70SZ08 | 108 | 6000 | 68.0 | 110 | 110 | 1.00 | 0.110 | 300 |

| GS70SZ09F | 108 | 1800 | 20.0 | 220 | 220 | 0.23 | 0.030 | |

| GS70SZ51 | 176 | 3000 | 55.0 | 24 | 24 | 4.00 | 0.570 | 200 |

| GS70SZ52 | 176 | 3000 | 55.0 | 27 | 27 | 3.50 | 0.500 | 200 |

| GS70SZ53 | 176 | 3000 | 55.0 | 48 | 48 | 1.90 | 0.310 | 200 |

| GS70SZ54 | 176 | 3000 | 55.0 | 110 | 110 | 0.80 | 0.130 | 200 |

| GS70SZ55 | 147 | 6000 | 92.0 | 24 | 24 | 6.00 | 0.570 | 300 |

| GS70SZ56 | 147 | 6000 | 92.0 | 27 | 27 | 5.40 | 0.500 | 300 |

| GS70SZ57 | 147 | 6000 | 92.0 | 48 | 48 | 3.00 | 0.310 | 300 |

| GS70SZ58 | 147 | 6000 | 92.0 | 110 | 110 | 1.20 | 0.130 | 300 |

| GS70SZ59 | 93 | 8000-10000 | 88.0 | 110 | 110 | 1.32 | 0.130 | 400 |

| GS70SZ61/H3 | 176 | 3000 | 55.0 | 27 | 27 | 3.50 | 0.490 | 200 |

| GS70SZ62/H2 | 398 | 6000 | 250.0 | 28 | 28 | 18.00 | 0.500 | |

| GS70SZ63/H3 | 147 | 6000 | 92.0 | 24 | 24 | 6.00 | 0.600 | 300 |

| GS70SZ64 | 127 | 3000 | 40.0 | 160 | 175 | 0.46 | 0.900 | 200 |

| GS70SZ65/H5 | 176 | 4500 | 83.0 | 36 | 36 | 3.50 | 0.320 | 250 |

| GS70SZ101 | 167 | 7500-9500 | 148.0 | 110 | 110 | 1.95 | 0.120 | 400 |

| GS70SZ101/H4 | 167 | 7500-9500 | 148.0 | 110 | 110 | 1.95 | 0.120 | 400 |

| GS70SZ103 | 294 | 2750 | 85.0 | 48 | 24 | 3.00 | 0.720 | 180 |

| GS70SZ104/H1 | 392 | 10000 | 410.0 | 27 | 27 | 30.00 | 0.600 | 500 |

| GS70SZ105/H2 | 539 | 6000 | 338.0 | 28 | 28 | 22.00 | 0.420 | |

| GS70SZ106 | 150 | 7000 | 110.0 | 200 | 200 | 0.75 | 0.083 | 350 |

Dimensional drawing

| Model | H | h | h1 | A | b | C | B | I | L | D | E | L4 | F | G | d | D2 | E2 | I12 | F1 | G2 | d2 | kg |

| – | – | – | (±0.25) | – | – | (±0.25) | – | – | h6 | – | – | +0.005 -0.015 |

h11 | H11 | h6 | – | – | +0.005 -0.015 |

h11 | H11 | ||

| GS70SZ01-49 | 42.5 | 79.5 | 5 | 74 | 90 | 22 | 39 | 55 | 114 | 6 | 12 | 16 | 2 | 4.3 | 7 | 5 | 12 | 13.5 | 2 | 3.3 | 7 | 1.5 |

| GS70SZ51-99 | 124 | 1.7 | ||||||||||||||||||||

| GS70SZ101-199 | 136 | 2 | ||||||||||||||||||||

| GS90SZ01-49 | 50 | 97.5 | 3 | 100 | 116 | 26.5 | 44 | 64 | 127 | 8 | 16 | 18 | 2 | 5.2 | 10 | 6 | 14 | 16 | 2 | 4.3 | 7 | 3 |

| GS90SZ51-99 | 40.5 | 147 | 3.8 | |||||||||||||||||||

| GS110SZ01-49 | 63 | 120.5 | 4 | 115 | 130 | 32 | 70 | 85 | 164 | 10 | 20 | 22 | 3 | 7.3 | 10 | 8 | 16 | 18 | 2 | 5.2 | 10 | 6.1 |

| GS110SZ51-99 | 47 | 194 | 7.9 |

Note:

If these models are not what you want, please freely tell us about your requirement. We will provide you with a suitable motor solution and price soon.

FAQ

1 Q: What’s your MOQ for gear motor and gearbox?

A: 1 unit is OK for different types.

2 Q: What about your warranty for your gear motor and gearbox?

A: One year.

3 Q: Do you provide OEM service with customer-logo?

A: Yes, we could do OEM orders.

4 Q: How about your payment terms ?

A: T/T, western union and paypal. 100% payment in advanced for orders less $10,000. 50% deposit and balance before delivery for orders over $10,000.

5 Q: How about your packing ?

A: Carton, plywood case and pallet

6 Q: What information should be given, if I buy gear motor and gearbox from you ?

A: Rated power, gearbox ratio, input speed, mounting position. More details, better!

7 Q: How do you deliver the gear motor and gearbox?

A: We will compare and choose the most suitable ways of delivery by sea, air or express courier after customer’s confirmation.

Warmly welcome your inquiry!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Household Appliances, Swimming Pool Cleaner |

|---|---|

| Operating Speed: | Adjust Speed |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Structure and Working Principle: | Brush |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there common issues or challenges associated with servo motor systems, and how can they be addressed?

Servo motor systems are widely used in various applications, but they can encounter common issues or challenges that affect their performance and reliability. Let’s explore some of these issues and discuss potential solutions:

1. Positioning and Tracking Errors:

One common challenge in servo motor systems is positioning and tracking errors. These errors can occur due to factors such as mechanical backlash, encoder resolution limitations, or disturbances in the system. To address this issue, careful calibration and tuning of the servo control system are necessary. This includes adjusting feedback gains, implementing feedback filtering techniques, and utilizing advanced control algorithms to improve the system’s accuracy and minimize errors. Additionally, employing high-resolution encoders and backlash compensation mechanisms can help enhance the positioning and tracking performance.

2. Vibration and Resonance:

Vibration and resonance can impact the performance of servo motor systems, leading to reduced accuracy and stability. These issues can arise from mechanical resonances within the system or external disturbances. To mitigate vibration and resonance problems, it is crucial to analyze the system’s dynamics and identify critical resonant frequencies. Implementing vibration dampening techniques such as mechanical isolation, using vibration-absorbing materials, or employing active vibration control methods can help minimize the effect of vibrations and improve the system’s performance.

3. Overheating and Thermal Management:

Servo motors can generate heat during operation, and inadequate thermal management can lead to overheating and potential performance degradation. To address this issue, proper cooling and thermal management techniques should be employed. This may involve using heat sinks, fans, or liquid cooling systems to dissipate heat efficiently. Ensuring adequate ventilation and airflow around the motor and avoiding excessive current or overloading can also help prevent overheating. Monitoring the motor’s temperature and implementing temperature protection mechanisms can further safeguard the motor from thermal damage.

4. Electrical Noise and Interference:

Electrical noise and interference can affect the performance and reliability of servo motor systems. These issues can arise from electromagnetic interference (EMI) or radio frequency interference (RFI) from nearby equipment or electrical sources. To mitigate electrical noise, proper shielding and grounding techniques should be employed. Using shielded cables, ferrite cores, and grounding the motor and control system can help minimize the impact of noise and interference. Additionally, employing filtering techniques and surge protection devices can further improve system robustness against electrical disturbances.

5. System Integration and Compatibility:

Integrating a servo motor system into a larger control system or automation setup can present challenges in terms of compatibility and communication. Ensuring proper compatibility between the servo motor and the control system is crucial. This involves selecting appropriate communication protocols, such as EtherCAT or Modbus, and ensuring compatibility with the control signals and interfaces. Employing standardized communication interfaces and protocols can facilitate seamless integration and interoperability. Additionally, thorough testing and verification of the system’s compatibility before deployment can help identify and address any integration issues.

6. Maintenance and Service:

Maintenance and service requirements are important considerations for servo motor systems. Regular maintenance, including lubrication, inspection, and cleaning, can help prevent issues related to wear and tear. Following manufacturer-recommended maintenance schedules and procedures is essential to ensure the longevity and optimal performance of the motor. In case of any malfunctions or failures, having access to technical support from the manufacturer or trained service personnel can help diagnose and address problems effectively.

By being aware of these common issues and challenges associated with servo motor systems and implementing appropriate solutions, it is possible to enhance the performance, reliability, and lifespan of the servo motor system. Regular monitoring, proactive maintenance, and continuous improvement can contribute to optimizing the overall operation and efficiency of the system.

How does the accuracy of a servo motor impact the precision of a system it operates in?

The accuracy of a servo motor has a significant impact on the precision of the system in which it operates. Here’s how the accuracy of a servo motor influences the precision of the system:

1. Positioning Control:

The accuracy of a servo motor directly affects the precision of positioning control in a system. A servo motor with high accuracy can accurately and consistently reach and maintain the desired position. This precision in positioning control is crucial in applications where precise movements, such as in robotics or manufacturing processes, are required. If the servo motor lacks accuracy, it may introduce position errors, leading to reduced precision in the system’s overall operation.

2. Repeatability:

Repeatability refers to the ability of a system to consistently achieve the same position or motion repeatedly. The accuracy of a servo motor plays a vital role in achieving high repeatability. A servo motor with high accuracy will consistently return to the same position when commanded to do so. This level of repeatability is essential in applications where consistent and precise movements are necessary, such as in assembly lines or pick-and-place operations. A lack of accuracy in the servo motor can result in variations in position from one cycle to another, reducing the overall precision of the system.

3. Error Compensation:

The accuracy of a servo motor is crucial for error compensation in a system. In many applications, external factors, such as variations in load or environmental conditions, can introduce errors in the system’s operation. An accurate servo motor can help compensate for these errors by precisely adjusting its position or motion based on feedback from sensors. This error compensation capability contributes to maintaining the precision of the system, as the servo motor can continuously adjust to minimize any deviations from the desired position or trajectory.

4. System Stability:

The accuracy of the servo motor also impacts the stability of the system. A servo motor with high accuracy can achieve stable movements and maintain control over the system’s dynamics. It can respond accurately to control signals, preventing overshoot, oscillations, or erratic behaviors that can degrade system precision. On the other hand, a servo motor with lower accuracy may introduce instability or erratic movements, compromising the overall precision of the system.

5. System Calibration and Calibration:

An accurate servo motor simplifies the calibration and fine-tuning process of a system. When a system requires calibration, an accurate servo motor provides a reliable reference point for adjustments. The precise and consistent movements of the servo motor make it easier to calibrate other components or subsystems in the system, ensuring that the entire system operates with the desired precision. If the servo motor lacks accuracy, it can be challenging to calibrate the system effectively, resulting in reduced precision in the system’s operation.

In summary, the accuracy of a servo motor has a direct impact on the precision of the system it operates in. An accurate servo motor enables precise positioning control, high repeatability, effective error compensation, system stability, and simplified calibration processes. These factors collectively contribute to achieving the desired precision in the system’s operation. Therefore, selecting a servo motor with the appropriate level of accuracy is crucial for ensuring the overall precision and performance of the system.

Can you explain the difference between a servo motor and a regular electric motor?

A servo motor and a regular electric motor are both types of electric motors, but they have distinct differences in terms of design, control, and functionality.

A regular electric motor, also known as an induction motor or a DC motor, is designed to convert electrical energy into mechanical energy. It consists of a rotor, which rotates, and a stator, which surrounds the rotor and generates a rotating magnetic field. The rotor is connected to an output shaft, and when current flows through the motor’s windings, it creates a magnetic field that interacts with the stator’s magnetic field, resulting in rotational motion.

On the other hand, a servo motor is a more specialized type of electric motor that incorporates additional components for precise control of position, speed, and acceleration. It consists of a regular electric motor, a sensor or encoder, and a feedback control system. The sensor or encoder provides feedback on the motor’s current position, and this information is used by the control system to adjust the motor’s behavior.

The key difference between a servo motor and a regular electric motor lies in their control mechanisms. A regular electric motor typically operates at a fixed speed based on the voltage and frequency of the power supply. In contrast, a servo motor can be controlled to rotate to a specific angle or position and maintain that position accurately. The control system continuously monitors the motor’s actual position through the feedback sensor and adjusts the motor’s operation to achieve the desired position or follow a specific trajectory.

Another distinction is the torque output of the motors. Regular electric motors generally provide high torque at low speeds and lower torque at higher speeds. In contrast, servo motors are designed to deliver high torque at both low and high speeds, which makes them suitable for applications that require precise and dynamic motion control.

Furthermore, servo motors often have a more compact and lightweight design compared to regular electric motors. They are commonly used in applications where precise positioning, speed control, and responsiveness are critical, such as robotics, CNC machines, automation systems, and remote-controlled vehicles.

In summary, while both servo motors and regular electric motors are used to convert electrical energy into mechanical energy, servo motors offer enhanced control capabilities, precise positioning, and high torque at various speeds, making them well-suited for applications that require accurate and dynamic motion control.

editor by CX 2024-02-25