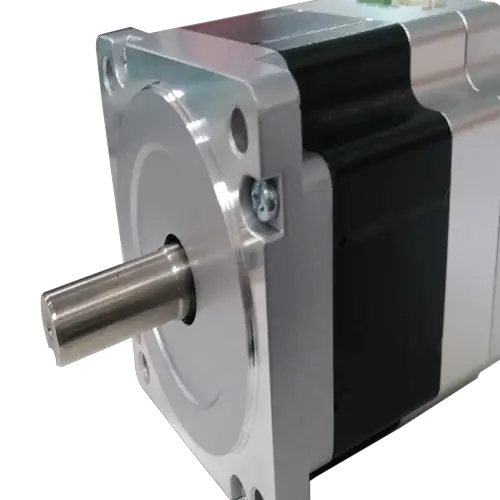

Integrated Servo Motor and Driver for AGV RGV Equipment

Our integrated servo motor and driver is a high-quality product manufactured by Sihong Motor Factory in China. It is an 80mm 1kw motor that runs at 3000rpm and generates 3.2nm of torque at 48V 72VDC. It is widely used in AGV RGV equipment, including stepper motor, electrical motor, brake motor, motor driver, gear motor, bldc motor, brushless motor, and servo motor applications. This motor is suitable for use in a variety of industries, including textile machinery, engraving machines, security, 4g antenna, solar energy, medical equipment, industrial automation, automobiles, office automation, printing equipment, and advertising equipment.

Product Description

This integrated servo motor and driver is a hot-selling product in China, with CE certification and high-quality standards. It can be customized according to your requirements, and its performance and parameters can be adjusted based on your needs. Our engineers can work from your motor diagram or sample to create a motor that meets your exact specifications.

Technical Parameters

The 80mm integrated servo motor and driver has the following technical specifications:

- Power: 1kw

- Speed: 3000rpm

- Torque: 3.2nm

- Voltage: 48V 72VDC

It has a high installation size, and our team can provide support during the installation process to ensure that it is properly installed and optimized for your specific application.

Other Industrial Products

In addition to our integrated servo motor and driver, our company supplies a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products at preferential prices, and our team provides thoughtful service to ensure that our customers are satisfied with our products. We welcome custom orders based on drawings and samples.

Frequently Asked Questions

1. Can the integrated servo motor and driver be customized?

Yes, our engineers can customize the performance and parameters of the motor based on your specific requirements.

2. What industries is the integrated servo motor and driver suitable for?

The integrated servo motor and driver is suitable for a wide range of industries, including textile machinery, engraving machines, security, 4g antenna, solar energy, medical equipment, industrial automation, automobiles, office automation, printing equipment, and advertising equipment.

3. What other industrial products do you supply?

In addition to the integrated servo motor and driver, we supply agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

4. Do you offer custom orders?

Yes, we welcome custom orders based on drawings and samples.

5. What is your approach to customer service?

Our team is dedicated to providing thoughtful service to ensure that our customers are satisfied with our products. We take pride in offering high-quality products at preferential prices.

Performance Characteristics of Servo Motor

– High Precision: Servo motors offer precise control and positioning, ensuring accurate movements in various applications.

– Fast Response: Servo motors have quick response times, allowing for rapid adjustments and precise positioning.

– High Torque: Servo motors can generate high torque output, enabling them to handle heavy loads with ease.

– Wide Speed Range: Servo motors can operate at varying speeds, making them suitable for applications that require different speed levels.

– Excellent Stability: Servo motors provide stable performance, maintaining position accuracy even in dynamic operating conditions.

– Smooth Operation: Servo motors offer smooth and precise motion control, reducing vibrations and ensuring smooth operation.

Types and Characteristics of Servo Motor

There are various types of servo motors available, each with its own unique characteristics:

– AC Servo Motors: AC servo motors are known for their high torque and excellent speed control.

– DC Servo Motors: DC servo motors are compact and offer quick response times, making them suitable for applications with limited space.

– Brushless Servo Motors: Brushless servo motors eliminate the need for brushes, resulting in low maintenance and longer lifespan.

– Linear Servo Motors: Linear servo motors provide linear motion, making them ideal for applications that require precise positioning along a straight path.

– Hybrid Servo Motors: Hybrid servo motors combine the benefits of stepper motors and servo motors, offering improved performance and control.

Advantages of Servo Motor Made of Different Materials

– Servo Motors with Aluminum Housing: Aluminum servo motors are lightweight, durable, and have excellent heat dissipation properties.

– Servo Motors with Stainless Steel Housing: Stainless steel servo motors are corrosion-resistant, making them suitable for harsh environments.

– Servo Motors with Plastic Housing: Plastic servo motors are cost-effective and lightweight, making them ideal for applications with weight restrictions.

Application of Servo Motor

Servo motors find extensive use in various industries:

– Industrial Automation: Servo motors play a crucial role in industrial automation systems, providing precise control and motion.

– Aerospace: Servo motors are employed in aerospace applications for their reliability and precise positioning capabilities.

– Automotive: Servo motors are used in automotive systems for applications such as power steering, throttle control, and braking systems.

– Medical Equipment: Servo motors are utilized in medical equipment for precise movements, such as robotic surgery systems and patient positioning.

– Consumer Electronics: Servo motors are found in consumer electronics devices, including cameras, drones, and home automation systems, for accurate control and positioning.

Future Development Trends and Opportunities

The servo motor industry is expected to witness the following trends and opportunities:

– Increased Demand for Miniature Servo Motors: As technology advances, the demand for smaller and more precise servo motors will rise.

– Growing Application in Robotics: With the increasing use of robotics in various industries, servo motors will play a vital role in robotic motion control.

– Integration with IoT: Servo motors integrated with IoT technology will enable remote monitoring and control, enhancing efficiency and productivity.

– Energy Efficiency: Future servo motors will focus on energy efficiency, reducing power consumption without compromising performance.

– Advancements in Control Algorithms: Improved control algorithms will lead to enhanced motion control and better performance of servo motors.

Choosing a Suitable Servo Motor

When selecting a servo motor, consider the following aspects:

– Power Requirements: Determine the power input and voltage requirements based on your application.

– Speed: Assess the required speed range and select a servo motor that can operate within that range.

– Torque: Consider the load requirements and choose a servo motor with sufficient torque output.

– Efficiency: Opt for a servo motor with high energy efficiency to minimize power consumption.

– Operating Environment: Evaluate the environmental conditions, such as temperature and humidity, and select a servo motor that can withstand them.

– Motor Type: Choose the appropriate type of servo motor based on your specific application requirements.

In conclusion, servo motors offer precise control, fast response, and high torque for various applications. Understanding their performance characteristics, types, and advantages in different materials is essential for selecting the right servo motor. Their widespread application in industries like industrial automation, aerospace, automotive, medical equipment, and consumer electronics highlights their significance. With the future trends and opportunities, servo motors are poised to continue playing a crucial role in the field of automation and robotics. Consider the power requirements, speed, torque, efficiency, operating environment, and motor type when choosing a suitable servo motor for your application.

Author: Dream