Product Description

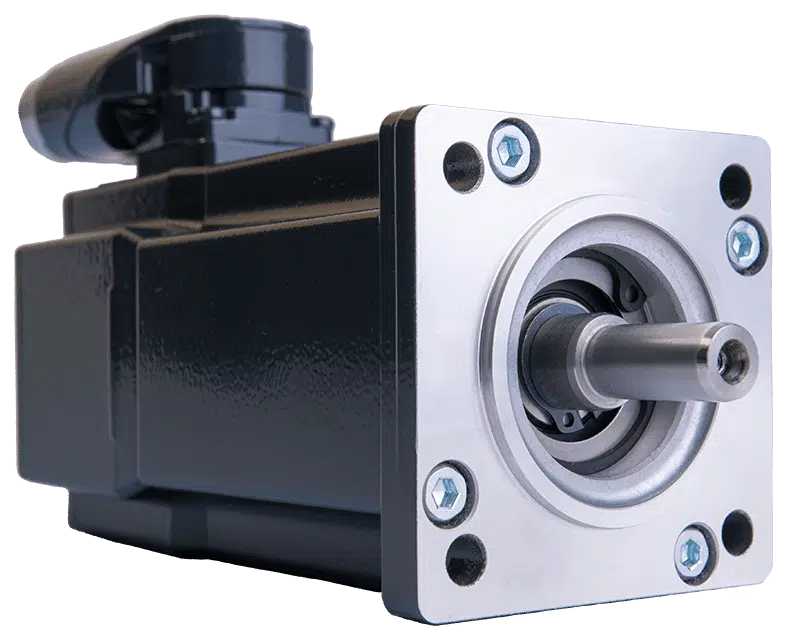

CE Quality China Factory 220VAC 600w 110 frame 2 N.m 2.5A servo motor for industrial robot arm for Laser Cutting Machine

SZGH-11060DC is 600 W servo motor ,optimizing design, compact, beautiful contour, long-term continuous working in rated working mode and economic type

Product Description

,Packing list :

1) SZGH-11060DC 600w servo motor -1pcs

2) SZGH-SD2004 220v servo driver – 1pcs

3) SZGH1MX-5M 5meter motor cables -1pcs

4) SZGH1EX-5M 5 meter encoder cables -1 pcs

5) Manual -1pcs

Pls tell us at first time when you need :

1) Brake motor

2) Absolutely encoder

3) long cables

Detailed Photos

Product Parameters

Description of Driver

Input Power : Single Three Phase AC220V-15%~+10% SO/60HZ

Control model :

0: Position Control; 1:Speed Control;

2: Torque Control; 3:Position/Speed Control;

4·PositionTorque Control: 5:Speed Torque Control

Protective Function : Over-speed Over-voltage Under-voltage Over-current OverloadEncoder Error/ Control Power Eror/ Position Offset Eror

Driver Load : Less than 3times of rotor inertia

Display : 5 bits LED indicator display 4 Operate keys

Communication : RS485

Position Control : Input Model , Electric Ratio

Certifications

Company Profile

HangZhou CHINAMFG Automation CO.,LTD (Formerly known as ‘HangZhou CHINAMFG Automation Co.,Limited(Built in 19 November 2571)’) is 1 of the leading CNC & automatic company in China, specialized in designing projects, marketing, and oversea trading, having extensive experience in CNC package solution, Our focus has been on providing the high quality of Industrial robot arm Lathe CNC system, Milling CNC system, Engraving CNC system, Grinding & router CNC system, Motor & driver, Spindle servo motor & driver, Gear reducer.

SZGH’ products have been in working with a wide variety of CNC machinery and automatic processing equipment with high performance and good precision, stably. We have now established a reliable structure , our experienced engineers and technicians are able to provide professional consultancy and offer you most suitable CNC application solution.

Our strict quality control measures guarantee excellent reliability and high standard of quality. Utilizing advanced CNC machinery to test every product, 100 percent inspection is made before packaging and shipment. Moreover, We also offer flexible lead times to support your business.

We have a large number of customers across Asia, America, the Middle East, Europe, South America, and Africa. Specially we already built own business corporate group in Middle East market.

Our Advantages

After Sales Service

Best & Professional after- sales supports

Our company have very professional engineers teams ;

We can provide the professional after -sales service to our all clients ;

Here is our engineer Mike solved the problems for our customer ;

Best supports !! Quicly reply !!

Buy at ease , use at ease !!!

FAQ

1. Who are we?

We are based in ZheJiang , China, start from 2013, which providing cnc total solutions&Robot arm, sell to Eastern Europe(20.00%),Mid East(20.00%),Southeast Asia(15.00%),Southern Europe(10.00%),South America(8.00%),North America(5.00%),Western Europe(5.00%),Eastern Asia(4.00%),Central America(4.00%),Northern Europe(4.00%),Africa(3.00%),Domestic Market(2.00%).

2. How can we guarantee quality?

Always finishing a pre full testing by our professional engineers;

Always final 100% Inspection before shipment;

3.What can you buy from us?

CNC Controller/Servo Motor & Servo Driver/Spindle Servo Motor & Spindle Servo Drive/Robot Arms

4. Why should you buy from us not from other suppliers?

We can provide with suitable package solution by CNC system and motor, drivers; Guanhong has professional technical team,customized design,high quality guarantee,competitive quotation, honest and reliable business is our tenet. Your satisfy is our greatest .

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,DDP,DDU,DAF;

Accepted Payment Currency:USD,EUR,CAD,HKD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian and so on.

6.When can you receive our order?

All goods will be produced well within 5 to 7 workdays, except the customized products.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machine Tool |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Single-Phase |

| Function: | Driving, Control |

| Casing Protection: | Explosion-Proof Type |

| Number of Poles: | 4 |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about servo motors and their applications?

Individuals interested in learning more about servo motors and their applications can access a variety of reliable resources. These resources provide valuable information, technical knowledge, and practical insights. Here are some places where individuals can find reliable resources for expanding their understanding of servo motors:

1. Manufacturer Websites:

Leading servo motor manufacturers often provide detailed documentation, technical specifications, application notes, and white papers on their websites. These resources offer in-depth information about their products, technologies, and best practices for servo motor applications. Users can visit the websites of prominent manufacturers to access reliable and up-to-date information.

2. Industry Associations and Organizations:

Industry associations and organizations related to automation, robotics, or specific industries often offer educational materials and resources on servo motors. They may provide technical publications, webinars, seminars, and training programs focused on servo motor technology and applications. Examples of such organizations include the International Society of Automation (ISA), the Robotics Industries Association (RIA), and the Society of Automotive Engineers (SAE).

3. Books and Technical Publications:

Books dedicated to servo motor technology, control systems, and industrial automation can provide comprehensive knowledge on the subject. Some recommended titles include “Servo Motors and Industrial Control Theory” by Riazollah Firoozian, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Servo Motors and Motion Control: An Introduction” by Albert F. Seabury. Technical publications and journals such as IEEE Transactions on Industrial Electronics and Control Engineering Practice also offer valuable insights and research findings.

4. Online Courses and Training Platforms:

Various online learning platforms offer courses and training programs focused on servo motors and their applications. Websites like Udemy, Coursera, and LinkedIn Learning provide access to video-based courses taught by industry experts. These courses cover topics such as servo motor fundamentals, motion control, programming, and troubleshooting. By enrolling in these courses, individuals can acquire structured knowledge and practical skills related to servo motors.

5. Technical Forums and Discussion Groups:

Participating in technical forums and discussion groups can be an effective way to learn from industry professionals and enthusiasts. Websites like Stack Exchange, Reddit, and engineering-focused forums host discussions on servo motors, where individuals can ask questions, share experiences, and gain insights from the community. It’s important to verify the credibility of the information shared in such forums and rely on responses from trusted contributors.

6. Trade Shows and Conferences:

Attending trade shows, exhibitions, and conferences related to automation, robotics, or specific industries can provide opportunities to learn about servo motors. These events often feature presentations, workshops, and demonstrations by industry experts and manufacturers. Participants can gain hands-on experience, interact with professionals, and stay updated with the latest advancements in servo motor technology.

By leveraging these reliable resources, individuals can deepen their knowledge and understanding of servo motors and their applications. It is advisable to consult multiple sources and cross-reference information to ensure a comprehensive understanding of the subject.

How does the accuracy of a servo motor impact the precision of a system it operates in?

The accuracy of a servo motor has a significant impact on the precision of the system in which it operates. Here’s how the accuracy of a servo motor influences the precision of the system:

1. Positioning Control:

The accuracy of a servo motor directly affects the precision of positioning control in a system. A servo motor with high accuracy can accurately and consistently reach and maintain the desired position. This precision in positioning control is crucial in applications where precise movements, such as in robotics or manufacturing processes, are required. If the servo motor lacks accuracy, it may introduce position errors, leading to reduced precision in the system’s overall operation.

2. Repeatability:

Repeatability refers to the ability of a system to consistently achieve the same position or motion repeatedly. The accuracy of a servo motor plays a vital role in achieving high repeatability. A servo motor with high accuracy will consistently return to the same position when commanded to do so. This level of repeatability is essential in applications where consistent and precise movements are necessary, such as in assembly lines or pick-and-place operations. A lack of accuracy in the servo motor can result in variations in position from one cycle to another, reducing the overall precision of the system.

3. Error Compensation:

The accuracy of a servo motor is crucial for error compensation in a system. In many applications, external factors, such as variations in load or environmental conditions, can introduce errors in the system’s operation. An accurate servo motor can help compensate for these errors by precisely adjusting its position or motion based on feedback from sensors. This error compensation capability contributes to maintaining the precision of the system, as the servo motor can continuously adjust to minimize any deviations from the desired position or trajectory.

4. System Stability:

The accuracy of the servo motor also impacts the stability of the system. A servo motor with high accuracy can achieve stable movements and maintain control over the system’s dynamics. It can respond accurately to control signals, preventing overshoot, oscillations, or erratic behaviors that can degrade system precision. On the other hand, a servo motor with lower accuracy may introduce instability or erratic movements, compromising the overall precision of the system.

5. System Calibration and Calibration:

An accurate servo motor simplifies the calibration and fine-tuning process of a system. When a system requires calibration, an accurate servo motor provides a reliable reference point for adjustments. The precise and consistent movements of the servo motor make it easier to calibrate other components or subsystems in the system, ensuring that the entire system operates with the desired precision. If the servo motor lacks accuracy, it can be challenging to calibrate the system effectively, resulting in reduced precision in the system’s operation.

In summary, the accuracy of a servo motor has a direct impact on the precision of the system it operates in. An accurate servo motor enables precise positioning control, high repeatability, effective error compensation, system stability, and simplified calibration processes. These factors collectively contribute to achieving the desired precision in the system’s operation. Therefore, selecting a servo motor with the appropriate level of accuracy is crucial for ensuring the overall precision and performance of the system.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-05-03