Product Description

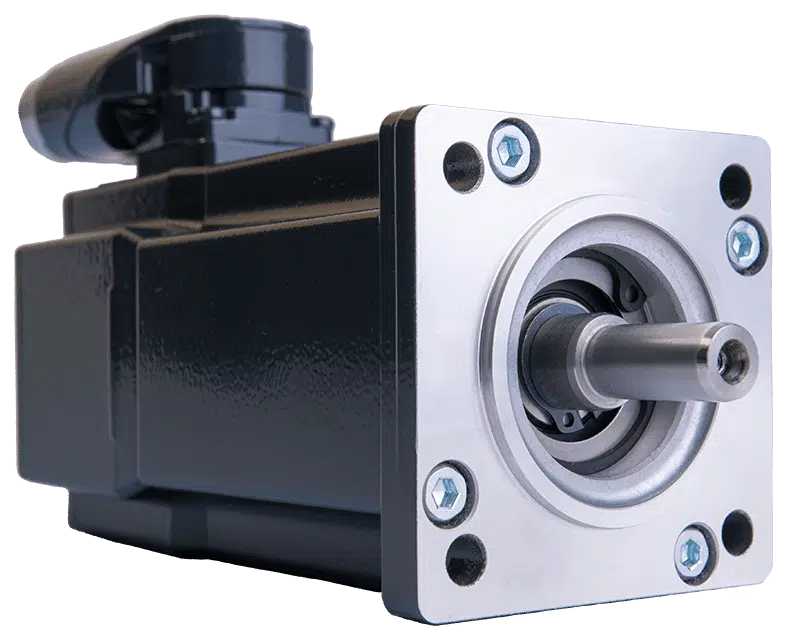

Structure and working principle of servo motor:

Servo motor is 1 of the commonly used motor,it is a motor that absolutely obeys the command of the control signal.Before the control signal is sent, the rotor is stationary;when the control signal is sent,the rotor rotates immediately;when the control signal disappears, the rotor can stop immediately.

As a special type of motor,synchronous servo motor is different from most other motors,it is designed for precise positioning,rather than speed controlling.

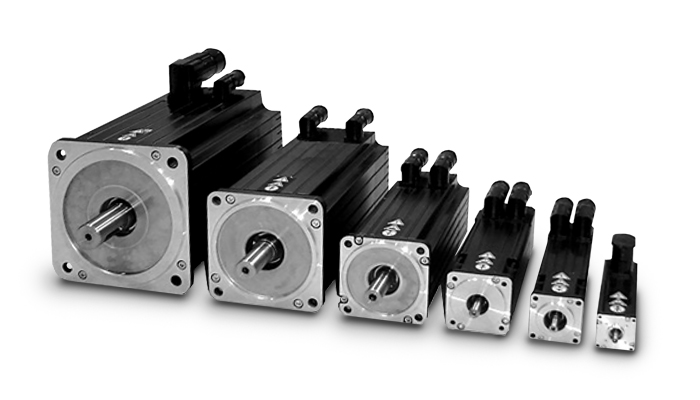

80ST,220V(1PHASE,3PHASE)

110ST,220V(1PHASE,3PHASE)

130ST,220V(1PHASE,3PHASE)

180ST,220V,380V

AC SERVO DRIVER,SG200

Since the development of AC servo technology in the early 1980s,the technology has become increasingly mature and the performance has been continuously improved.Now it has been widely used in CNC machine tools, printing and packaging machinery,textile machinery,automatic production lines and other fields.

SG Series AC servo is a new generation of AC servo driver independently developed by our company. It mainly uses the latest 32-bit DSP as the core remote computing unit, and adopts complex programmable device EPLD and CHINAMFG intelligent power module.It has a series advantages such as high integration,small size,fast response,perfect protection, and high reliability.

Using temperature:-10ºC-55ºC

Humidity:less than 90%(No condensation)

Vibration:less than 0.5g(4.9m/s2)

Working duty:continuously

Technical parameter:

| Model | SG200 Series | ||

| Input power supply | Single phase or 3 phase,AC220v(-15%-20%,50/60Hz) | Three phase, AC220v(-15%-20%,50/60Hz) | |

| Use environment | Temperature | Using:0°C-55°C;Storage:-20°C-80°C | |

| Humidity | Below 90%(no condensation) | ||

| Control mode | Position control;Speed control;Torque control;Jog control | ||

| Regenerative braking | Built-in | ||

| Control characteristics | Speed frequency response | <400Hz | |

| Speed fluctuation rate | <±0.03(load 0-100);<±0.02(power -15%-10%),the value corresponds to the rated speed | ||

| Pulse frequency | ≤500kHz | ||

| Control Input | servo enable; alarm clear; ccw drive prohibited; cw drive prohibited; Deviation counter clearing/speed selection 1/zero speed clamping; Command pulse prohibited/speed selection 2 | ||

| Control output | servo is ready to output; servo alarm output; position finish output/speed arrive output ;mechanical brake output | ||

| Position Control | Input method | pulse+symbol; ccw pulse/cw pulse; 2phase A/B quadrature pulses | |

| Electronic gear | 1-32767/1-32767 | ||

| Feedback pulse | 2500lines/rotation | ||

| Protection function | Overspeed, overvoltage and undervoltage of main power supply, overcurrent, overload, braking abnormality, encoder abnormality, control power abnormality, position out-of-tolerance, etc | ||

| Monitoring function | Speed, current position, command pulse accumulation, position deviation, motor torque, motor current, linear speed, rotor absolute position, command pulse frequency, operation status, input and output terminal signal, etc | ||

AC SERVO DRIVER,M SERIES

| Model | M Series | ||

| Input power supply | Single phase or 3 phase 220VAC | Three phase 220VAC | |

| Control mode | Single phase or 3 phase full wave rectification/PWM control sine wave drive mode | ||

| Encoder feedback | 2500 lines incremental encoder,17bit,23bit absolute encoder | ||

| Pulse signal input | Direction+pulse;A/B phase orthogonal pulse;CW/CCW pulse | ||

| Differential input:500Kpps | |||

| Open collector input:200Kpps | |||

| Digital input | 8-channel digital input,which can allocate and change signals | ||

| Analog input | 2-channel analog input function | ||

| Communication interface | RS-232:applicable servo driver debugging;RS-485:applicable for customer on-site networking communication | ||

| Control mode | Position control;speed control;torque control;position/speed control;speed/torque control;position/torque control | ||

| Basic performance | Response band width:3KHz | ||

| Speed adjust range:1-8000rpm | |||

| Troque control accuraccy:±2% | |||

| Speed variation rate:≤0.5% | |||

| Soft start time setting:0-60S | |||

| Built-in function | Motor load inertia identification function,vibration suppression function,feedforward compensation function,various PID control strategies | ||

| Overtravel prevention function,emergency parking brake in case of overtravel | |||

| Electronic gear ratio function:electronic gear ratio can be set arbitrarily | |||

| 16 stage position control function,16 stage speed control function,interrupted fixed length function | |||

| Protection function | Over voltage, over current, overload,overspeed,under voltage,overheating,encoder failure,power phase loss,abnormal regenerative braking,fan failure,etc | ||

| Use environment | Temperature | Using:0°C-45°C;Storage:-20°C-85°C | |

| Humidity | Below 90%(no condensation) | ||

| Protection | IP20 | ||

| Altitude | Below 1000m | ||

| Vibration | Below 4.9m/s2 | ||

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Operating Speed: | Constant Speed |

| Operation Mode: | Electric Motor |

| Magnetic Structure: | Permanent Magnet |

| Function: | Driving |

| Number of Poles: | 4 |

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended for ensuring the longevity of servo motors?

Maintaining servo motors properly is crucial to ensure their longevity and reliable performance. Here are some recommended maintenance practices:

1. Regular Cleaning:

Regularly clean the servo motor to remove dust, debris, and other contaminants that can affect its performance. Use a soft brush or compressed air to clean the motor’s exterior and ventilation ports. Avoid using excessive force or liquid cleaners that could damage the motor.

2. Lubrication:

Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant for the motor. Lubricate the motor’s bearings, gears, and other moving parts as per the specified schedule. Proper lubrication reduces friction, minimizes wear, and helps maintain optimal performance.

3. Inspections:

Regularly inspect the servo motor for signs of wear, damage, or loose connections. Check for any unusual noises, vibrations, or overheating during operation, as these can indicate potential issues. If any abnormalities are detected, consult the manufacturer’s documentation or seek professional assistance for further evaluation and repair.

4. Electrical Connections:

Ensure that all electrical connections to the servo motor, such as power cables and signal wires, are secure and properly insulated. Loose or damaged connections can lead to electrical problems, voltage fluctuations, or signal interference, which can affect the motor’s performance and longevity.

5. Environmental Considerations:

Take into account the operating environment of the servo motor. Ensure that the motor is protected from excessive moisture, dust, extreme temperatures, and corrosive substances. If necessary, use appropriate enclosures or protective measures to safeguard the motor from adverse environmental conditions.

6. Software and Firmware Updates:

Stay updated with the latest software and firmware releases provided by the servo motor manufacturer. These updates often include bug fixes, performance enhancements, and new features that can improve the motor’s functionality and reliability. Follow the manufacturer’s instructions for safely updating the motor’s software or firmware.

7. Training and Documentation:

Ensure that personnel responsible for the maintenance of servo motors are properly trained and familiar with the manufacturer’s guidelines and documentation. This includes understanding recommended maintenance procedures, safety precautions, and troubleshooting techniques. Regular training and access to up-to-date documentation are essential for effective servo motor maintenance.

8. Professional Servicing:

If a servo motor requires complex repairs or servicing beyond regular maintenance, it is advisable to consult a qualified technician or contact the manufacturer’s service center. Attempting to repair or modify the motor without proper expertise can lead to further damage or safety hazards.

By following these maintenance practices, servo motors can operate optimally and have an extended lifespan. Regular cleaning, lubrication, inspections, secure electrical connections, environmental considerations, software updates, training, and professional servicing all contribute to ensuring the longevity and reliable performance of servo motors.

How does the accuracy of a servo motor impact the precision of a system it operates in?

The accuracy of a servo motor has a significant impact on the precision of the system in which it operates. Here’s how the accuracy of a servo motor influences the precision of the system:

1. Positioning Control:

The accuracy of a servo motor directly affects the precision of positioning control in a system. A servo motor with high accuracy can accurately and consistently reach and maintain the desired position. This precision in positioning control is crucial in applications where precise movements, such as in robotics or manufacturing processes, are required. If the servo motor lacks accuracy, it may introduce position errors, leading to reduced precision in the system’s overall operation.

2. Repeatability:

Repeatability refers to the ability of a system to consistently achieve the same position or motion repeatedly. The accuracy of a servo motor plays a vital role in achieving high repeatability. A servo motor with high accuracy will consistently return to the same position when commanded to do so. This level of repeatability is essential in applications where consistent and precise movements are necessary, such as in assembly lines or pick-and-place operations. A lack of accuracy in the servo motor can result in variations in position from one cycle to another, reducing the overall precision of the system.

3. Error Compensation:

The accuracy of a servo motor is crucial for error compensation in a system. In many applications, external factors, such as variations in load or environmental conditions, can introduce errors in the system’s operation. An accurate servo motor can help compensate for these errors by precisely adjusting its position or motion based on feedback from sensors. This error compensation capability contributes to maintaining the precision of the system, as the servo motor can continuously adjust to minimize any deviations from the desired position or trajectory.

4. System Stability:

The accuracy of the servo motor also impacts the stability of the system. A servo motor with high accuracy can achieve stable movements and maintain control over the system’s dynamics. It can respond accurately to control signals, preventing overshoot, oscillations, or erratic behaviors that can degrade system precision. On the other hand, a servo motor with lower accuracy may introduce instability or erratic movements, compromising the overall precision of the system.

5. System Calibration and Calibration:

An accurate servo motor simplifies the calibration and fine-tuning process of a system. When a system requires calibration, an accurate servo motor provides a reliable reference point for adjustments. The precise and consistent movements of the servo motor make it easier to calibrate other components or subsystems in the system, ensuring that the entire system operates with the desired precision. If the servo motor lacks accuracy, it can be challenging to calibrate the system effectively, resulting in reduced precision in the system’s operation.

In summary, the accuracy of a servo motor has a direct impact on the precision of the system it operates in. An accurate servo motor enables precise positioning control, high repeatability, effective error compensation, system stability, and simplified calibration processes. These factors collectively contribute to achieving the desired precision in the system’s operation. Therefore, selecting a servo motor with the appropriate level of accuracy is crucial for ensuring the overall precision and performance of the system.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-02-05