Product Description

GSK ZJY265A-15BH-B3A2Y1

mechanical characteristics curve of the motor

Motor overall and installation dimension

| Overall dimension (refer to figures) | |||||||||||||||||

| A | B | C | D | E | F | G | H | I | J | K | L | N | P | Q | S | T | Z |

| 265 | 132 | 185 | 265 | 110 | 532 | 392 | 230h7 | 14 | 48h6 | 256 | 135 | 230 | 40 | 315 | 110 | 5 | 15 |

Dimension of the Standard Key Slot

| Product Features |

| ·Adopt the totally enclosed air cooling structure without the shell,good shape and compact structure. |

| ·Employ the optimized electromagnetic design with the characters of the low noise,smooth running and high efficiency. |

| ·Introduce the imported bearing in high precision,and the rotor reaches the high precision with the dynamic balance process, which can ensure the motor running stable and reliable with small vibration and low noise in the maximum rotational speed range. |

| ·Adopt the enameled wire of corona resistance,the motor can be driven reliably at the ambient temperature of -15 degree to 40 degree, and in the environment with the dust and oil. |

| ·Employ the encoder at high speed and in high precision,and it can be incorporated into the drive with high performance for controlling the speed and the position in high precision. |

| ·The overload capacity is strong and the motor is wide and the maximum speed can reach 12000rpm. |

| ·Impact resistance,long lifetime and high cost performance. |

| ·Protection level IP54(GB/T4942.1-2006) |

| ·Insulation grade:Grade F(GB 755-2008) |

| ·Vibration grade:Grade B(GB 10068-2008) |

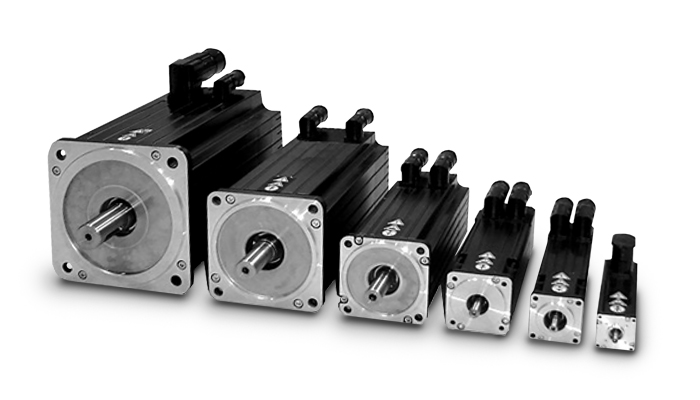

Product Description

GSK ZJY series spindle servo motor

Models Numbers

| SR.NO | Meaning |

| (1) | The spindle servo motor |

| (2) | Flange size ( 182, 208, 265, 320 ) |

| (3) | Design sequence number (None: Original A, B,C… : design sequence number) |

| (4) | Rated power (Unit:KW) |

| (5) | Rated speed (V: 600 r/min, W: 750 r/min, A: 1000 r/min, B:1500 r/min, C: 2000 r/min, E: 3000 r/min ) |

| (6) | Max. speed (G: 15000 r/min,F: 12000 r/min, H:10000 r/min, M:7000 r/min, L:4500 r/min ) |

| (7) | D:Dual-Speed type |

| (8) | Structure installation type: (B5 flange installation, B3 footing installation, B35 flange & footing installation ) |

| (9) | Encoder type (None: Incremental 1571 p/r, A2: Incremental 5000 p/r, A5: Absolute 21 bit ) |

| (10) | Look the terminal box position in view from the shaft end (None: on the top, R: on the right, L: on the left). |

| (11) | Shaft end (None: straight shaft , Y1: with the standard key slot) |

| (12) | Customer special order numbers are bracketed in two capitals. |

| (13) | Power supply voltage (none: three-phase 380~440V, L: three-phase 220V) |

Product Parameters

The main technical parameters of three-phase 380V/440V spindle motor and its overall dimension(List 1-1)

| Model | ZJY182A-3.7BL | ZJY182A-5.5BL | ZJY182A-1.5BH | ZJY182A-2.2BH | ZJY182A-3.7BH | ZJY182A-5.5BH | ZJY182A-3.7EG | ZJY182A-5.5EG | ZJY182A-7.5EG | |

| Item | ||||||||||

| Rated power(kW) | 3.7 | 5.5 | 1.5 | 2.2 | 3.7 | 5.5 | 3.7 | 5.5 | 7.5 | |

| Adaptive driver | GS/GR3050 | GS/GR3050 | GS/GR3048 | GS/GR3048 | GS/GR3050 | GS/GR3075 | GS/GR3050 | GS/GR3075 | GS/GR3100 | |

| Drive power supply(V) | Three-phase AC 380/440V 50/60Hz | |||||||||

| Rated current(A) | 10.4 | 13.8 | 7.3 | 7.5 | 15.5 | 17.3 | 11.6 | 16.6 | 20.2 | |

| Rated | 53.7 | 53.5 | 53.9 | 53.6 | 53.1 | 53.5 | 103.2 | 103.3 | 103.2 | |

| frequency(Hz) | ||||||||||

| Rated torque(N·m) | 24 | 35 | 9.5 | 14 | 24 | 35 | 11.8 | 17.5 | 24 | |

| 30min power(kW) | 5.5 | 7.5 | 2.2 | 3.7 | 5.5 | 7.5 | 5.5 | 7.5 | 11 | |

| 30min current(A) | 14.8 | 18 | 9.3 | 11 | 19.6 | 21.8 | 15.4 | 20.7 | 26.6 | |

| 30min torque(N·m) | 35 | 48 | 14 | 24 | 35 | 48 | 17.5 | 24 | 35 | |

| Rated speed(r/min) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 3000 | 3000 | 3000 | |

| Constant power range(r/min) | 1500~4500 | 1500~4500 | 1500~8000 | 1500~8000 | 1500~8000 | 1500~8000 | 3000~12000 | 3000~12000 | 3000-12000 | |

| Max. speed(r/min) | 4500 | 4500 | 10000 | 10000 | 10000 | 10000 | 15000 | 15000 | 15000 | |

| Moment of inertia(kg·m2) | 0.0068 | 0.5712 | 0.004 | 0.0054 | 0.0083 | 0.5712 | 0.0054 | 0.0068 | 0.0083 | |

| Weight(kg) | 37 | 52 | 27 | 32 | 43 | 52 | 32 | 37 | 43 | |

| Installation type | IM B5 or B35 | |||||||||

| Cooling fan power supply | Three-phase AC 380~440V 50/60Hz 37W 0.1A | |||||||||

| Overall dimension (refer to figures) |

A | 182 | 182 | 182 | 182 | 182 | 182 | 182 | 182 | 182 |

| B | 91 | 91 | 91 | 91 | 91 | 91 | 91 | 91 | 91 | |

| C | 123 | 123 | 123 | 123 | 123 | 123 | 123 | 123 | 123 | |

| D | 185 | 185 | 185 | 185 | 185 | 185 | 185 | 185 | 185 | |

| E | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| F | 371 | 436 | 319 | 346 | 401 | 436 | 346 | 371 | 401 | |

| G | 249 | 314 | 197 | 224 | 279 | 314 | 224 | 249 | 279 | |

| H | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | |

| I | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

| J | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | |

| K | 158 | 158 | 158 | 158 | 158 | 158 | 158 | 158 | 158 | |

| L | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | |

| N | 156 | 156 | 156 | 156 | 156 | 156 | 156 | 156 | 156 | |

| P | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | |

| Q | 184 | 249 | 132 | 159 | 214 | 249 | 159 | 184 | 214 | |

| S | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| T | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Z | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

The main technical parameters of three-phase 380V/440V spindle motor and its overall dimension(List 1-2)

| Model | ZJY208A-3.7WL | ZJY208A-2.2AM | ZJY208A-3.7AM | ZJY208A-5.5AM | ZJY208A-5.5BL | ZJY208A-7.5BL | ZJY208A-9BL | ZJY208A-3.7BM | |

| Item | |||||||||

| Rated power(kW) | 3.7 | 2.2 | 3.7 | 5.5 | 5.5 | 7.5 | 9 | 3.7 | |

| Adaptive driver | GS/GR3050 | GS/GR3048 | GS/GR3050 | GS/GR3075 | GS/GR3075 | GS/GR3075 | GS/GR3100 | GS/GR3050 | |

| Drive power supply(V) | Three-phase AC 380/440V 50/60Hz | ||||||||

| Rated current(A) | 11.3 | 6.7 | 10.2 | 16.3 | 12.9 | 17.9 | 21.6 | 8.6 | |

| Rated | 27.3 | 35.7 | 35.7 | 35.7 | 53.3 | 52.9 | 52.6 | 52.9 | |

| frequency(Hz) | |||||||||

| Rated torque(N·m) | 47 | 21 | 35 | 53 | 35 | 48 | 57.3 | 24 | |

| 30min power(kW) | 5.5 | 3.7 | 5.5 | 7.5 | 7.5 | 11 | 12 | 5.5 | |

| 30min current(A) | 16 | 10.6 | 14.2 | 20.5 | 16.8 | 24 | 27.2 | 12.7 | |

| 30min torque(N·m) | 70 | 35 | 53 | 72 | 48 | 70 | 76.4 | 35 | |

| Rated speed(r/min) | 750 | 1000 | 1000 | 1000 | 1500 | 1500 | 1500 | 1500 | |

| Constant power range(r/min) | 750~3500 | 1000~4000 | 1000~4000 | 1000~4000 | 1500~4500 | 1500~4500 | 1500~4500 | 1500-5000 | |

| Max. speed(r/min) | 4500 | 7000 | 7000 | 7000 | 4500 | 4500 | 4500 | 7000 | |

| Moment of inertia(kg·m2) | 0.571 | 0.0142 | 0.0196 | 0.571 | 0.0143 | 0.0196 | 0.5716 | 0.0142 | |

| Weight(kg) | 77 | 51 | 66 | 77 | 51.5 | 66 | 77.5 | 51 | |

| Installation type | IM B5 or B35 | ||||||||

| Cooling fan power supply | Three-phase AC 380~440V 50/60Hz 40W 0.14A | ||||||||

| Overall dimension (refer to figures) |

A | 208 | 208 | 208 | 208 | 208 | 208 | 208 | 208 |

| B | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | |

| C | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | |

| D | 215 | 215 | 215 | 215 | 215 | 215 | 215 | 215 | |

| E | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| F | 524 | 414 | 469 | 524 | 414 | 469 | 524 | 414 | |

| G | 395 | 285 | 340 | 395 | 285 | 340 | 395 | 285 | |

| H | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | |

| I | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | |

| J | 38h6 | 28h6 | 38h6 | 38h6 | 38h6 | 38h6 | 48h6 | 28h6 | |

| K | 212 | 212 | 212 | 212 | 212 | 212 | 212 | 212 | |

| L | 106 | 106 | 106 | 106 | 106 | 106 | 106 | 106 | |

| N | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | |

| P | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| Q | 320 | 210 | 265 | 320 | 210 | 265 | 320 | 210 | |

| S | 80 | 60 | 80 | 80 | 80 | 80 | 110 | 60 | |

| T | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Z | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

The main technical parameters of three-phase 380V/440V spindle motor and its overall dimension(List 1-3)

| Model | ZJY208A-5.5BM | ZJY208A-7.5BM | ZJY208A-2.2BH | ZJY208A-3.7BH | ZJY208A-5.5BH | ZJY208A-7.5BH | ZJY208A-11CM | ZJY208A-11CH | |

| Item | |||||||||

| Rated power(kW) | 5.5 | 7.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 11 | |

| Adaptive driver | GS/GR3050 | GS/GR3075 | GS/GR3048 | GS/GR3050 | GS/GR3075 | GS/GR3100 | GS/GR3100 | GS/GR3100 | |

| Drive power supply(V) | Three-phase AC 380/440V 50/60Hz | ||||||||

| Rated current(A) | 13 | 17 | 8.9 | 12.6 | 18.4 | 22.4 | 28.3 | 28.3 | |

| Rated | 52.4 | 52.7 | 52.6 | 52.5 | 52.4 | 52.6 | 69.1 | 69 | |

| frequency(Hz) | |||||||||

| Rated torque(N·m) | 35 | 48 | 14 | 24 | 35 | 48 | 52.6 | 52.5 | |

| 30min power(kW) | 7.5 | 11 | 3.7 | 5.5 | 7.5 | 11 | 15 | 15 | |

| 30min current(A) | 16.9 | 24.6 | 13.8 | 18 | 24 | 32.2 | 37 | 37 | |

| 30min torque(N·m) | 48 | 70 | 24 | 35 | 48 | 70 | 71.6 | 71.6 | |

| Rated speed(r/min) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 2000 | 2000 | |

| Constant power range(r/min) | 1500~5000 | 1500~5000 | 1500~5000 | 1500~5000 | 1500~8000 | 1500~8000 | 2000~7000 | 2000-8000 | |

| Max. speed(r/min) | 7000 | 7000 | 10000 | 10000 | 10000 | 10000 | 7000 | 10000 | |

| Moment of inertia(kg·m2) | 0.0196 | 0.571 | 0.0093 | 0.0142 | 0.0196 | 0.571 | 0.5716 | 0.571 | |

| Weight(kg) | 66 | 77 | 49 | 51 | 66 | 77 | 77.5 | 77 | |

| Installation type | IM B5 or B35 | ||||||||

| Cooling fan power supply | Three-phase AC 380~440V 50/60Hz 40W 0.14A | ||||||||

| Overall dimension (refer to figures) |

A | 208 | 208 | 208 | 208 | 208 | 208 | 208 | 208 |

| B | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | |

| C | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | |

| D | 215 | 215 | 215 | 215 | 215 | 215 | 215 | 215 | |

| E | 80 | 80 | 60 | 60 | 80 | 80 | 110 | 80 | |

| F | 469 | 524 | 364 | 414 | 469 | 524 | 524 | 524 | |

| G | 340 | 395 | 235 | 285 | 340 | 395 | 395 | 395 | |

| H | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | |

| I | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | |

| J | 38h6 | 38h6 | 28h6 | 28h6 | 38h6 | 38h6 | 48h6 | 38h6 | |

| K | 212 | 212 | 212 | 212 | 212 | 212 | 212 | 212 | |

| L | 106 | 106 | 106 | 106 | 106 | 106 | 106 | 106 | |

| N | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | |

| P | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| Q | 265 | 320 | 160 | 210 | 265 | 320 | 320 | 320 | |

| S | 80 | 80 | 53 | 60 | 80 | 80 | 110 | 80 | |

| T | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Z | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

The main technical parameters of three-phase 380V/440V spindle motor and its overall dimension(List 1-4)

| Model | ZJY208A-5.5CF | ZJY208A-7.5CF | ZJY208A-11EH | ZJY208A-5.5EF | ZJY208A-7.5EF | ZJY208A-11EF | ZJY265A-5.5WL | ZJY265A-7.5WL | ||

| Item | ||||||||||

| Rated power(kW) | 5.5 | 7.5 | 11 | 5.5 | 7.5 | 11 | 5.5 | 7.5 | ||

| Adaptive driver | GS/GR3075 | GS/GR3100 | GS/GR3100 | GS/GR3050 | GS/GR3075 | GS/GR3100 | GS/GR3075 | GS/GR3100 | ||

| Drive power supply(V) | Three-phase AC 380/440V 50/60Hz | |||||||||

| Rated current(A) | 19 | 25.8 | 25.2 | 12.8 | 17.7 | 25.2 | 16.3 | 21.4 | ||

| Rated | 69 | 69 | 102.2 | 102.9 | 102.2 | 102.2 | 26.6 | 26.7 | ||

| frequency(Hz) | ||||||||||

| Rated torque(N·m) | 26.3 | 35.8 | 35 | 17.5 | 24 | 35 | 70 | 95.5 | ||

| 30min power(kW) | 7.5 | 11 | 15 | 7.5 | 11 | 15 | 7.5 | 11 | ||

| 30min current(A) | 24 | 34.9 | 31.6 | 16 | 23.3 | 31.7 | 20.8 | 30.1 | ||

| 30min torque(N·m) | 35.8 | 52.5 | 48 | 24 | 35 | 48 | 95.5 | 140 | ||

| Rated speed(r/min) | 2000 | 2000 | 3000 | 3000 | 3000 | 3000 | 750 | 750 | ||

| Constant power range(r/min) | 2000~10000 | 2000~10000 | 3000~9000 | 3000~10000 | 3000~10000 | 3000~10000 | 750~3500 | 750-3500 | ||

| Max. speed(r/min) | 12000 | 12000 | 10000 | 12000 | 12000 | 12000 | 4500 | 4500 | ||

| Moment of inertia(kg·m2) | 0.0142 | 0.0196 | 0.0196 | 0.0093 | 0.0142 | 0.0196 | 0.0606 | 0. 0571 | ||

| Weight(kg) | 51 | 66 | 66 | 49 | 51 | 66 | 107 | 125 | ||

| Installation type | IM B5 or B35 | IM B5 or B3 | ||||||||

| Cooling fan power supply | Three-phase AC 380~440V 50/60Hz 40W 0.14A | Three-phase AC 380~440V 50/60Hz 70W 0.21A | ||||||||

| Overall dimension (refer to figures) |

A | 208 | 208 | 208 | 208 | 208 | 208 | 265 | 265 | |

| B | 104 | 104 | 104 | 104 | 104 | 104 | 132 | 132 | ||

| C | 160 | 160 | 160 | 160 | 160 | 160 | 185 | 185 | ||

| D | 215 | 215 | 215 | 215 | 215 | 215 | 265 | 265 | ||

| E | 60 | 80 | 80 | 60 | 60 | 80 | 110 | 110 | ||

| F | 414 | 469 | 469 | 364 | 414 | 469 | 487 | 533 | ||

| G | 285 | 340 | 340 | 235 | 285 | 340 | 347 | 392 | ||

| H | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 230h7 | 230h7 | ||

| I | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

| J | 28h6 | 38h6 | 38h6 | 28h6 | 28h6 | 38h6 | 48h6 | 48h6 | ||

| K | 212 | 212 | 212 | 212 | 212 | 212 | 256 | 256 | ||

| L | 106 | 106 | 106 | 106 | 106 | 106 | 135 | 135 | ||

| N | 180 | 180 | 180 | 180 | 180 | 180 | 230 | 230 | ||

| P | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | ||

| Q | 210 | 265 | 265 | 160 | 210 | 265 | 270 | 315 | ||

| S | 60 | 80 | 80 | 60 | 60 | 80 | 110 | 110 | ||

| T | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | ||

| Z | 12 | 12 | 12 | 12 | 12 | 12 | 15 | 15 | ||

The main technical parameters of three-phase 380V/440V spindle motor and its overall dimension(List 1-5)

| Model | ZJY265A-11WL | ZJY265A-7.5AM | ZJY265A-11AM | ZJY265A-15AM | ZJY265A-7.5BM | ZJY265A-11BM | ZJY265A-15BM | ZJY265A-18.5BM | ZJY265A-22BM | |

| Item | ||||||||||

| Rated power(kW) | 11 | 7.5 | 11 | 15 | 7.5 | 11 | 15 | 18.5 | 22 | |

| Adaptive driver | GS/GR3148 | GS/GR3100 | GS/GR3148 | GS/GR3150 | GS/GR3075 | GS/GR3100 | GS/GR3150 | GS/GR3150 | GS/GR3198 | |

| Drive power supply(V) | Three-phase AC 380/440V 50/60Hz | |||||||||

| Rated current(A) | 30 | 21.5 | 30.9 | 48.3 | 18 | 26 | 35 | 48.7 | 58 | |

| Rated | 27.2 | 35.2 | 35.2 | 35.1 | 52.3 | 52.2 | 51.9 | 51.8 | 51.7 | |

| frequency(Hz) | ||||||||||

| Rated torque(N·m) | 140 | 72 | 105 | 143 | 48 | 70 | 95 | 118 | 140 | |

| 30min power(kW) | 15 | 11 | 15 | 18.5 | 11 | 15 | 18.5 | 22 | 30 | |

| 30min current(A) | 41 | 29 | 40.2 | 56 | 26 | 34 | 42 | 54.7 | 73 | |

| 30min torque(N·m) | 191 | 105 | 143 | 177 | 70 | 95 | 118 | 140 | 191 | |

| Rated speed(r/min) | 750 | 1000 | 1000 | 1000 | 1500 | 1500 | 1500 | 1500 | 1500 | |

| Constant power range(r/min) | 750~3500 | 1000~4000 | 1000~4000 | 1000~4000 | 1500~5000 | 1500~5000 | 1500~5000 | 1500~5000 | 1500-5000 | |

| Max. speed(r/min) | 4500 | 7000 | 7000 | 7000 | 7000 | 7000 | 7000 | 7000 | 7000 | |

| Moment of inertia(kg·m2) | 0. 0571 | 0. 0571 | 0.571 | 0.0869 | 0. 0571 | 0.571 | 0.571 | 0.571 | 0.1043 | |

| Weight(kg) | 143 | 89 | 125 | 143 | 89 | 107 | 125 | 143 | 162 | |

| Installation type | IM B5 or B35 | |||||||||

| Cooling fan power supply | Three-phase AC 380~440V 50/60Hz 70W 0.21A | |||||||||

| Overall dimension (refer to figures) |

A | 265 | 265 | 265 | 265 | 265 | 265 | 265 | 265 | 265 |

| B | 132 | 132 | 132 | 132 | 132 | 132 | 132 | 132 | 132 | |

| C | 185 | 185 | 185 | 185 | 185 | 185 | 185 | 185 | 185 | |

| D | 265 | 265 | 265 | 265 | 265 | 265 | 265 | 265 | 265 | |

| E | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | |

| F | 577 | 442 | 532 | 577 | 442 | 487 | 532 | 577 | 632 | |

| G | 437 | 302 | 392 | 437 | 302 | 347 | 392 | 437 | 492 | |

| H | 230h7 | 230h7 | 230h7 | 230h7 | 230h7 | 230h7 | 230h7 | 230h7 | 230h7 | |

| I | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | |

| J | 55h6 | 48h6 | 48h6 | 48h6 | 48h6 | 48h6 | 48h6 | 55h6 | 55h6 | |

| K | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | |

| L | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | 135 | |

| N | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 | |

| P | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| Q | 360 | 225 | 315 | 360 | 225 | 270 | 315 | 360 | 415 | |

| S | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | |

| T | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Z | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

The main technical parameters of three-phase 380V/440V spindle motor and its overall dimension(List 1-6)

| Model | ZJY265A-7.5BH | ZJY265A-11BH | ZJY265A-15BH | ZJY320A-18.5WL | ZJY320A-22WL | ZJY320A-30BL | ZJY320A-37BL | ZJY320A-45BL | |

| Item | |||||||||

| Rated power(kW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | |

| Adaptive driver | GS/GR3100 | GS/GR3148 | GS/GR3150 | GS/GR3198 | GS/GR3198 | GS/GR3300 | GS/GR3300 | GS/GR3300 | |

| Drive power supply(V) | Three-phase AC 380/440V 50/60Hz | ||||||||

| Rated current(A) | 21 | 30 | 40.7 | 51 | 58 | 69 | 87 | 100 | |

| Rated | 51.7 | 51.7 | 51.7 | 26.1 | 26 | 51.2 | 51.1 | 51.1 | |

| frequency(Hz) | |||||||||

| Rated torque(N·m) | 48 | 70 | 95 | 235 | 280 | 191 | 235 | 286 | |

| 30min power(kW) | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | |

| 30min current(A) | 28.5 | 38.3 | 42.7 | 59 | 73 | 83 | 102 | 115 | |

| 30min torque(N·m) | 70 | 95 | 118 | 280 | 381 | 235 | 286 | 352 | |

| Rated speed(r/min) | 1500 | 1500 | 1500 | 750 | 750 | 1500 | 1500 | 1500 | |

| Constant power range(r/min) | 1500~8000 | 1500~8000 | 1500~8000 | 750~3500 | 750~3500 | 1500~4500 | 1500~4500 | 1500~4500 | |

| Max. speed(r/min) | 10000 | 10000 | 10000 | 4500 | 4500 | 4500 | 4500 | 4500 | |

| Moment of inertia(kg·m2) | 0. 0571 | 0.571 | 0.571 | 0.2997 | 0.345 | 0.24 | 0.2997 | 0.348 | |

| Weight(kg) | 89 | 107 | 125 | 249 | 285 | 208 | 249 | 293 | |

| Installation type | IM B5 or B3 | IM B35 | |||||||

| Cooling fan power supply | Three-phase AC 380~440V 50/60Hz 70W 0.21A | Three-phase AC 380~440V 50/60Hz 60W 0.22A | |||||||

| Overall dimension (refer to figures) |

A | 265 | 265 | 265 | 320 | 320 | 320 | 320 | 320 |

| B | 132 | 132 | 132 | \ | \ | \ | \ | \ | |

| C | 185 | 185 | 185 | 193 | 193 | 193 | 193 | 193 | |

| D | 265 | 265 | 265 | 350 | 350 | 350 | 350 | 350 | |

| E | 110 | 110 | 110 | 140 | 140 | 140 | 140 | 140 | |

| F | 442 | 487 | 532 | 715 | 765 | 645 | 715 | 785 | |

| G | 302 | 347 | 392 | 450 | 500 | 380 | 450 | 520 | |

| H | 230h7 | 230h7 | 230h7 | 300h7 | 300h7 | 300h7 | 300h7 | 300h7 | |

| I | 14 | 14 | 14 | 19 | 19 | 19 | 19 | 19 | |

| J | 48h6 | 48h6 | 48h6 | 60h6 | 60h6 | 60h6 | 60h6 | 60h6 | |

| K | 256 | 256 | 256 | \ | \ | \ | \ | \ | |

| L | 135 | 135 | 135 | 165 | 165 | 165 | 165 | 165 | |

| N | 230 | 230 | 230 | 279 | 279 | 279 | 279 | 279 | |

| P | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | |

| Q | 225 | 270 | 315 | 529 | 579 | 459 | 529 | 599 | |

| S | 110 | 110 | 110 | \ | \ | \ | \ | \ | |

| T | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Z | 15 | 15 | 15 | 19 | 19 | 19 | 19 | 19 | |

The main technical parameters of three-phase 220V spindle motor and its overall dimension(List 2-1)

| Model | ZJY182A-3.7BL | ZJY182A-5.5BL | ZJY182A-1.5BH | ZJY182A-2.2BH | ZJY182A-3.7BH | ZJY182A-5.5BH | ZJY182A-3.7EG | ZJY182A-5.5EG | ZJY182A-7.5EG | |

| Item | ||||||||||

| Rated power(kW) | 3.7 | 5.5 | 1.5 | 2.2 | 3.7 | 5.5 | 3.7 | 5.5 | 7.5 | |

| Adaptive driver | GS/GR2075 | GS/GR2100 | GS/GR2050 | GS/GR2050 | GS/GR2100 | GS/GR2100 | GS/GR2100 | GS/GR2100 | GS/GR2148 | |

| Drive power supply(V) | Three-phase AC 220V 50/60Hz | |||||||||

| Rated current(A) | 17.9 | 23.9 | 10.7 | 12.9 | 23.5 | 30 | 20 | 28.8 | 35 | |

| Rated | 53.7 | 53.5 | 53.9 | 53.6 | 53.1 | 53.5 | 103.2 | 103.3 | 103.2 | |

| frequency(Hz) | ||||||||||

| Rated torque(N·m) | 24 | 35 | 9.5 | 14 | 24 | 35 | 11.8 | 17.5 | 24 | |

| 30min power(kW) | 5.5 | 7.5 | 2.2 | 3.7 | 5.5 | 7.5 | 5.5 | 7.5 | 11 | |

| 30min current(A) | 25.2 | 31.1 | 17.6 | 20 | 36.4 | 40.7 | 26.7 | 35.8 | 47.3 | |

| 30min torque(N·m) | 35 | 48 | 14 | 24 | 35 | 48 | 17.5 | 24 | 35 | |

| Rated speed(r/min) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 3000 | 3000 | 3000 | |

| Constant power range(r/min) | 1500-4500 | 1500-4500 | 1500~8000 | 1500~8000 | 1500~8000 | 1500~8000 | 3000~12000 | 3000~12000 | 3000~12000 | |

| Max. speed(r/min) | 4500 | 4500 | 10000 | 10000 | 10000 | 10000 | 15000 | 15000 | 15000 | |

| Moment of inertia(kg·m2) | 0.0068 | 0.5712 | 0.004 | 0.0054 | 0.0083 | 0.5712 | 0.0054 | 0.0068 | 0.0083 | |

| Weight(kg) | 37 | 52 | 27 | 32 | 43 | 52 | 32 | 37 | 43 | |

| Installation type | IM B5 or B35 | |||||||||

| Cooling fan power supply | Three-phase AC 220V 50/60Hz 37W 0.1A | |||||||||

| Overall dimension (refer to figures) |

A | 182 | 182 | 182 | 182 | 182 | 182 | 182 | 182 | 182 |

| B | 91 | 91 | 91 | 91 | 91 | 91 | 91 | 91 | 91 | |

| C | 123 | 123 | 123 | 123 | 123 | 123 | 123 | 123 | 123 | |

| D | 185 | 185 | 185 | 185 | 185 | 185 | 185 | 185 | 185 | |

| E | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| F | 371 | 436 | 319 | 346 | 401 | 436 | 346 | 371 | 401 | |

| G | 249 | 314 | 197 | 224 | 279 | 314 | 224 | 249 | 279 | |

| H | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | 150h7 | |

| I | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

| J | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | 28h6 | |

| K | 184 | 184 | 158 | 158 | 158 | 158 | 158 | 158 | 158 | |

| L | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | 93 | |

| N | 156 | 156 | 156 | 156 | 156 | 156 | 156 | 156 | 156 | |

| P | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | |

| Q | 184 | 249 | 132 | 159 | 214 | 249 | 159 | 184 | 214 | |

| S | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| T | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Z | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

The main technical parameters of three-phase 220V spindle motor and its overall dimension(List 2-2)

| Model | ZJY208A-3.7WL | ZJY208A-2.2AM | ZJY208A-3.7AM | ZJY208A-5.5AM | ZJY208A-5.5BL | ZJY208A-7.5BL | ZJY208A-9BL | ZJY208A-3.7BM | |

| Item | |||||||||

| Rated power(kW) | 3.7 | 2.2 | 3.7 | 5.5 | 5.5 | 7.5 | 9 | 3.7 | |

| Adaptive driver | GS/GR2075 | GS/GR2050 | GS/GR2075 | GS/GR2100 | GS/GR2100 | GS/GR2100 | GS/GR2148 | GS/GR2075 | |

| Drive power supply(V) | Three-phase AC 220V 50/60Hz | ||||||||

| Rated current(A) | 19.6 | 11.6 | 17.7 | 28.2 | 22.4 | 31 | 37.5 | 14.9 | |

| Rated | 27.3 | 35.7 | 35.7 | 35.7 | 53.3 | 52.9 | 52.6 | 52.9 | |

| frequency(Hz) | |||||||||

| Rated torque(N·m) | 47 | 21 | 35 | 53 | 35 | 48 | 57.3 | 24 | |

| 30min power(kW) | 5.5 | 3.7 | 5.5 | 7.5 | 7.5 | 11 | 12 | 5.5 | |

| 30min current(A) | 27.3 | 18.4 | 24.6 | 35.5 | 28 | 41.3 | 46.2 | 22 | |

| 30min torque(N·m) | 70 | 35 | 53 | 72 | 48 | 70 | 76.4 | 35 | |

| Rated speed(r/min) | 750 | 1000 | 1000 | 1000 | 1500 | 1500 | 1500 | 1500 | |

| Constant power range(r/min) | 750-3500 | 1000-4000 | 1000~4000 | 1000~4000 | 1500~4500 | 1500~4500 | 1500~4500 | 1500~5000 | |

| Max. speed(r/min) | 4500 | 7000 | 7000 | 7000 | 4500 | 4500 | 4500 | 7000 | |

| Moment of inertia(kg·m2) | 0.571 | 0.0142 | 0.0196 | 0.571 | 0.0143 | 0.0196 | 0.571 | 0.0142 | |

| Weight(kg) | 77 | 51 | 66 | 77 | 51.5 | 66 | 77.5 | 51 | |

| Installation type | IM B5 or B35 | ||||||||

| Cooling fan power supply | Three-phase AC 220V 50/60Hz 40W 0.14A | ||||||||

| Overall dimension (refer to figures) |

A | 208 | 208 | 208 | 208 | 208 | 208 | 208 | 208 |

| B | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | |

| C | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | |

| D | 215 | 215 | 215 | 215 | 215 | 215 | 215 | 215 | |

| E | 80 | 60 | 80 | 80 | 80 | 80 | 110 | 60 | |

| F | 524 | 414 | 469 | 524 | 414 | 469 | 524 | 414 | |

| G | 395 | 285 | 340 | 395 | 285 | 340 | 395 | 285 | |

| H | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | 180h7 | |

| I | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | |

| J | 38h6 | 28h6 | 38h6 | 38h6 | 38h6 | 38h6 | 48h6 | 28h6 | |

| K | 212 | 212 | 212 | 212 | 212 | 212 | 212 | 212 | |

| L | 106 | 106 | 106 | 106 | 106 | 106 | 106 | 106 | |

| N | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | |

| P | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| Q | 320 | 210 | 265 | 320 | 210 | 265 | 320 | 210 | |

| S | 80 | 80 | 80 | 80 | 80 | 80 | 110 | 60 | |

| T | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Z | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

The main technical parameters of three-phase 220V spindle motor and its overall dimension(List 2-3)

The main technical parameters of three-phase 220V spindle motor and its overall dimension(List 2-4)

The main technical parameters of three-phase 220V spindle motor and its overall dimension(List 2-5)

The main technical parameters of dual speed motor and its overall dimension(List 3)

Company Profile

GSK CNC Equipment Co., Ltd.

GSK CNC Equipment Co., Ltd. (hereinafter referred as GSK) is specially devoted to conducting research and practice of basic equipment industrial development, providing “trinity” packaged solutions of machine tool CNC system, servo drive and servo motor, taking initiative in the expansion of industrial robot and all-electric injection molding machine field, developing the new marketing mode of machine tool exhibition hall, providing the customers with all-round professional machine tool remanufacturing solutions and services, promoting the integration of production and education, setting up the vocational education and training institute, as well as conducting highly skilled CNC personnel training. It has developed into a high-tech enterprise integrating science, education, industry and trade, thus being known as “China Southern CNC Industrial Base”.

Adhering to the corporate philosophy of “making itself a century-old enterprise and building gold quality” and the service spirit of “keeping improvement and making users satisfied”, GSK enhances the user product value & benefits through continuous technological progress and innovation, and makes unremitting efforts to promote the localization process of basic equipment industry, improve the technological level of the industry, and promote the development of China’s national equipment manufacturing industry.

Main products:

GSK CNC System Idustrial robot

Full electric injection molding machine CNC machine

I nternational exhibition

Exhibition hall

218MC USB Reading Problem Solution

2 18MC USB Reading Problem Solution

FAQ

Payments

1) We can accept EXW, FOB

2) Payment must be made before shipment.

3) Import duties, taxes and charges are not included in the item price or shipping charges. These charges are the buyer’s responsibility.

Shipping

1) We only ship to your confirmed address. Please make sure your shipping address is correct before purchase.

2) Most orders will be shipped out within 3-7 working days CHINAMFG payment confirmation.

3) Shipping normally takes 7-25 working days. Most of the items will delivery in 2 weeks, while there will be a delay for something we cannot control (such as the bad weather). If it happens, just contact us, we will help you check and resolve any problem.

3) Please check the package CHINAMFG receipt, if there are some damages, please contact us immediately.

Feedback & Refund

1) Feedback is important to us, if you have any problem with our products, please contact us, our technician will give you useful advises.

2) When you have the parcel and not satisfied with the goods or it is other problem, please tell us immediately, and provide us a photo showing the detail.

3) Any reason requiring for all refund. Items must be in original condition and no physical damage. Buyer responsible for all shipping cost.

If you need more information, please contact with us. We will attach great importance to your any problems.

Hope we could establish a long-term effective cooperation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Protection Type |

| Starting Mode: | Auto-induction Voltage-reduced Starting |

| Customization: |

Available

|

|

|---|

How does the cost of servo motors vary based on their specifications and features?

The cost of servo motors can vary significantly based on their specifications and features. Several factors influence the price of servo motors, and understanding these factors can help in selecting the most cost-effective option for a specific application. Let’s explore in detail how the cost of servo motors can vary:

1. Power Rating:

One of the primary factors affecting the cost of a servo motor is its power rating, which is typically measured in watts or kilowatts. Higher power-rated servo motors generally cost more than lower-rated ones due to the increased materials and manufacturing required to handle higher power levels. The power rating of a servo motor is determined by the torque and speed requirements of the application. Higher torque and speed capabilities often correspond to higher costs.

2. Torque and Speed:

The torque and speed capabilities of a servo motor directly impact its cost. Servo motors designed for high torque and high-speed applications tend to be more expensive due to the need for robust construction, specialized materials, and advanced control electronics. Motors with higher torque and speed ratings often require more powerful magnets, larger windings, and higher precision components, contributing to the increase in cost.

3. Frame Size:

The physical size or frame size of a servo motor also plays a role in determining its cost. Servo motors come in various frame sizes, such as NEMA (National Electrical Manufacturers Association) standard sizes in North America. Larger frame sizes generally command higher prices due to the increased materials and manufacturing complexity required to build larger motors. Smaller frame sizes, on the other hand, may be more cost-effective but may have limitations in terms of torque and speed capabilities.

4. Feedback Mechanism:

The feedback mechanism used in a servo motor affects its cost. Servo motors typically employ encoders or resolvers to provide feedback on the rotor position. Higher-resolution encoders or more advanced feedback technologies can increase the cost of the motor. For example, servo motors with absolute encoders, which provide position information even after power loss, tend to be more expensive than those with incremental encoders.

5. Control Features and Technology:

The control features and technology incorporated into a servo motor can influence its cost. Advanced servo motors may offer features such as built-in controllers, fieldbus communication interfaces, advanced motion control algorithms, or integrated safety functions. These additional features contribute to the cost of the motor but can provide added value and convenience in certain applications. Standard servo motors with basic control functionality may be more cost-effective for simpler applications.

6. Brand and Reputation:

The brand and reputation of the servo motor manufacturer can impact its cost. Established and reputable brands often command higher prices due to factors such as quality assurance, reliability, technical support, and extensive product warranties. While motors from less-known or generic brands may be more affordable, they may not offer the same level of performance, reliability, or long-term support.

7. Customization and Application-Specific Requirements:

If a servo motor needs to meet specific customization or application-specific requirements, such as specialized mounting options, environmental sealing, or compliance with industry standards, the cost may increase. Customization often involves additional engineering, design, and manufacturing efforts, which can lead to higher prices compared to off-the-shelf servo motors.

It’s important to note that the cost of a servo motor is not the sole indicator of its quality or suitability for a particular application. It is essential to carefully evaluate the motor’s specifications, features, and performance characteristics in relation to the application requirements to make an informed decision.

In summary, the cost of servo motors varies based on factors such as power rating, torque and speed capabilities, frame size, feedback mechanism, control features and technology, brand reputation, and customization requirements. By considering these factors and comparing different options, it is possible to select a servo motor that strikes the right balance between performance and cost-effectiveness for a specific application.

Can you explain the concept of torque and speed in relation to servo motors?

Torque and speed are two essential parameters in understanding the performance characteristics of servo motors. Let’s explore these concepts in relation to servo motors:

Torque:

Torque refers to the rotational force produced by a servo motor. It determines the motor’s ability to generate rotational motion and overcome resistance or load. Torque is typically measured in units of force multiplied by distance, such as Nm (Newton-meter) or oz-in (ounce-inch).

The torque output of a servo motor is crucial in applications where the motor needs to move or control a load. The motor must provide enough torque to overcome the resistance or friction in the system and maintain the desired position or motion. Higher torque allows the motor to handle heavier loads or more challenging operating conditions.

It is important to note that the torque characteristics of a servo motor may vary depending on the speed or position of the motor. Manufacturers often provide torque-speed curves or torque-position curves, which illustrate the motor’s torque capabilities at different operating points. Understanding these curves helps in selecting a servo motor that can deliver the required torque for a specific application.

Speed:

Speed refers to the rotational velocity at which a servo motor operates. It indicates how fast the motor can rotate and how quickly it can achieve the desired position or motion. Speed is typically measured in units of revolutions per minute (RPM) or radians per second (rad/s).

The speed of a servo motor is crucial in applications that require rapid movements or high-speed operations. It determines the motor’s responsiveness and the system’s overall performance. Different servo motors have different speed capabilities, and the maximum achievable speed is often specified by the manufacturer.

It is worth noting that the speed of a servo motor may also affect its torque output. Some servo motors exhibit a phenomenon known as “speed-torque curve,” where the motor’s torque decreases as the speed increases. This behavior is influenced by factors such as motor design, winding resistance, and control algorithms. Understanding the speed-torque characteristics of a servo motor is important for selecting a motor that can meet the speed requirements of the application while maintaining sufficient torque.

Overall, torque and speed are interrelated parameters that determine the performance capabilities of a servo motor. The torque capability determines the motor’s ability to handle loads, while the speed capability determines how quickly the motor can achieve the desired motion. When selecting a servo motor, it is essential to consider both the torque and speed requirements of the application to ensure that the motor can deliver the desired performance.

How does feedback control work in a servo motor system?

In a servo motor system, feedback control plays a crucial role in achieving precise control over the motor’s position, speed, and acceleration. The feedback control loop consists of several components that work together to continuously monitor and adjust the motor’s behavior based on the desired and actual position information. Here’s an overview of how feedback control works in a servo motor system:

1. Position Reference:

The servo motor system starts with a position reference or a desired position. This can be specified by a user or a control system, depending on the application requirements. The position reference represents the target position that the servo motor needs to reach and maintain.

2. Feedback Sensor:

A feedback sensor, such as an encoder or resolver, is attached to the servo motor’s shaft. The purpose of the feedback sensor is to continuously measure the motor’s actual position and provide feedback to the control system. The sensor generates signals that indicate the motor’s current position, allowing the control system to compare it with the desired position.

3. Control System:

The control system receives the position reference and the feedback signals from the sensor. It processes this information to determine the motor’s current position error, which is the difference between the desired position and the actual position. The control system calculates the required adjustments to minimize this position error and bring the motor closer to the desired position.

4. Controller:

The controller is a key component of the feedback control loop. It receives the position error from the control system and generates control signals that govern the motor’s behavior. The controller adjusts the motor’s inputs, such as voltage or current, based on the position error and control algorithm. The control algorithm can be implemented using various techniques, such as proportional-integral-derivative (PID) control, which adjusts the motor’s inputs based on the current error, the integral of past errors, and the rate of change of errors.

5. Motor Drive:

The control signals generated by the controller are sent to the motor drive unit, which amplifies and converts these signals into appropriate voltage or current levels. The motor drive unit provides the necessary power and control signals to the servo motor to initiate the desired motion. The drive unit adjusts the motor’s inputs based on the control signals to achieve the desired position, speed, and acceleration specified by the control system.

6. Motor Response:

As the motor receives the adjusted inputs from the motor drive, it starts to rotate and move towards the desired position. The motor’s response is continually monitored by the feedback sensor, which measures the actual position in real-time.

7. Feedback Comparison:

The feedback sensor compares the actual position with the desired position. If there is any deviation, the sensor generates feedback signals reflecting the discrepancy between the desired and actual positions. These signals are fed back to the control system, allowing it to recalculate the position error and generate updated control signals to further adjust the motor’s behavior.

This feedback loop continues to operate in a continuous cycle, with the control system adjusting the motor’s inputs based on the feedback information. As a result, the servo motor can accurately track and maintain the desired position, compensating for any disturbances or variations that may occur during operation.

In summary, feedback control in a servo motor system involves continuously comparing the desired position with the actual position using a feedback sensor. The control system processes this position error and generates control signals, which are converted and amplified by the motor drive unit to drive the motor. The motor’s response is monitored by the feedback sensor, and any discrepancies are fed back to the control system, enabling it to make further adjustments. This closed-loop control mechanism ensures precise positioning and accurate control of the servo motor.

editor by CX 2024-03-05