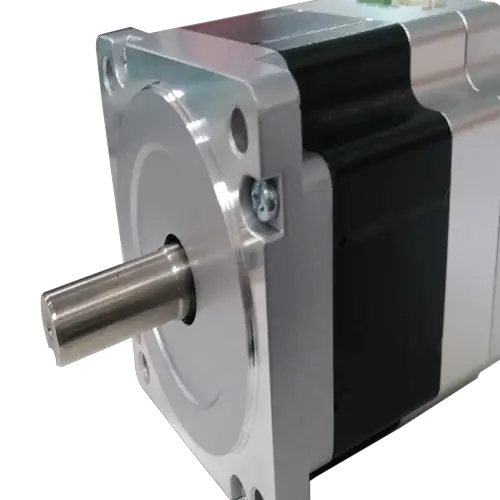

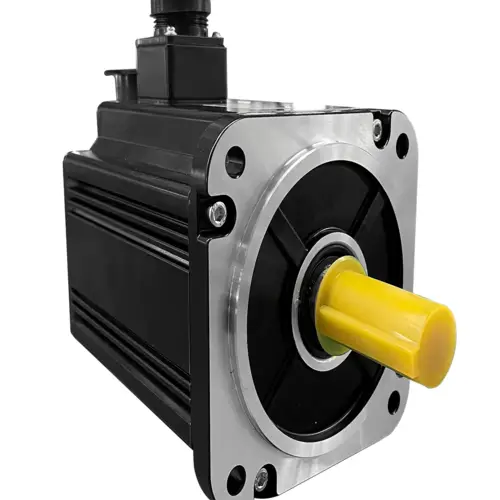

New Fanuc AC Servo Motor A06b-2063-B107

This AC servo motor is a top-quality product manufactured in China. It is available for purchase with a 12-month warranty and can be shipped via DHL or FedEx. The motor has been designed for use with air compressors and is highly portable, making it a versatile option for a range of industries.

Product Description

This AC servo motor is an original, high-quality product that is made in Japan. Its model number is A06B-2063-B107, and it is 100% original and in perfect condition. The motor will be delivered within 10 workdays, and it has a lead time of 7 days. It will be shipped via FedEx or DHL, and payment can be made using L/C, T/T, or Money Gram.

The motor is accompanied by detailed photos that show its condition and quality. It will be packed in a professional anti-static bag to ensure its safety during delivery.

Packaging & Shipping

We will ship the motor within 7 working days after payment is received. All goods are tested before shipment to ensure that they are in perfect working order. The motor will be packed in a professional anti-static bag to ensure its safety during delivery.

Our advantages

- We offer a one-year warranty for all new products and a two-month warranty for used products.

- Our prices are at least 10% lower than the market price.

- We offer fast delivery (5-10 days ETD) via DHL, the fastest service available.

- We test every part before delivery to ensure that it is in perfect working order.

- We offer both PayPal and wire transfer payment options.

Our company specializes in supplying a range of industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on offering high-quality products at preferential prices, and we provide thoughtful services to all of our customers. We welcome custom orders based on drawings and samples.

FAQ

1. What is the warranty period for this product?

A: We provide a 12-month warranty for all the items we offer, and you can return any item with quality problems within 15 days.

2. How do your prices compare to those of other suppliers?

A: We believe in creating more benefits for customers, so if you find a better price elsewhere, please let us know, and we will do our best to meet your price and support you.

3. What shipping options do you offer?

A: We have DHL freight forwarders with competitive prices, and customers can also use their own freight forwarders.

4. Do you offer technical support?

A: Yes, with our professional technology, we can help customers solve technical problems.

5. Can I customize my order based on drawings and samples?

A: Yes, we welcome custom orders based on drawings and samples.

Performance Characteristics of Servo Motor

– High Precision: Servo motors offer precise control and positioning, ensuring accurate movements in various applications.

– Fast Response: Servo motors have quick response times, allowing for rapid adjustments and precise positioning.

– High Torque: Servo motors can generate high torque output, enabling them to handle heavy loads with ease.

– Wide Speed Range: Servo motors can operate at varying speeds, making them suitable for applications that require different speed levels.

– Excellent Stability: Servo motors provide stable performance, maintaining position accuracy even in dynamic operating conditions.

– Smooth Operation: Servo motors offer smooth and precise motion control, reducing vibrations and ensuring smooth operation.

Types and Characteristics of Servo Motor

There are various types of servo motors available, each with its own unique characteristics:

– AC Servo Motors: AC servo motors are known for their high torque and excellent speed control.

– DC Servo Motors: DC servo motors are compact and offer quick response times, making them suitable for applications with limited space.

– Brushless Servo Motors: Brushless servo motors eliminate the need for brushes, resulting in low maintenance and longer lifespan.

– Linear Servo Motors: Linear servo motors provide linear motion, making them ideal for applications that require precise positioning along a straight path.

– Hybrid Servo Motors: Hybrid servo motors combine the benefits of stepper motors and servo motors, offering improved performance and control.

Advantages of Servo Motor Made of Different Materials

– Servo Motors with Aluminum Housing: Aluminum servo motors are lightweight, durable, and have excellent heat dissipation properties.

– Servo Motors with Stainless Steel Housing: Stainless steel servo motors are corrosion-resistant, making them suitable for harsh environments.

– Servo Motors with Plastic Housing: Plastic servo motors are cost-effective and lightweight, making them ideal for applications with weight restrictions.

Application of Servo Motor

Servo motors find extensive use in various industries:

– Industrial Automation: Servo motors play a crucial role in industrial automation systems, providing precise control and motion.

– Aerospace: Servo motors are employed in aerospace applications for their reliability and precise positioning capabilities.

– Automotive: Servo motors are used in automotive systems for applications such as power steering, throttle control, and braking systems.

– Medical Equipment: Servo motors are utilized in medical equipment for precise movements, such as robotic surgery systems and patient positioning.

– Consumer Electronics: Servo motors are found in consumer electronics devices, including cameras, drones, and home automation systems, for accurate control and positioning.

Future Development Trends and Opportunities

The servo motor industry is expected to witness the following trends and opportunities:

– Increased Demand for Miniature Servo Motors: As technology advances, the demand for smaller and more precise servo motors will rise.

– Growing Application in Robotics: With the increasing use of robotics in various industries, servo motors will play a vital role in robotic motion control.

– Integration with IoT: Servo motors integrated with IoT technology will enable remote monitoring and control, enhancing efficiency and productivity.

– Energy Efficiency: Future servo motors will focus on energy efficiency, reducing power consumption without compromising performance.

– Advancements in Control Algorithms: Improved control algorithms will lead to enhanced motion control and better performance of servo motors.

Choosing a Suitable Servo Motor

When selecting a servo motor, consider the following aspects:

– Power Requirements: Determine the power input and voltage requirements based on your application.

– Speed: Assess the required speed range and select a servo motor that can operate within that range.

– Torque: Consider the load requirements and choose a servo motor with sufficient torque output.

– Efficiency: Opt for a servo motor with high energy efficiency to minimize power consumption.

– Operating Environment: Evaluate the environmental conditions, such as temperature and humidity, and select a servo motor that can withstand them.

– Motor Type: Choose the appropriate type of servo motor based on your specific application requirements.

In conclusion, servo motors offer precise control, fast response, and high torque for various applications. Understanding their performance characteristics, types, and advantages in different materials is essential for selecting the right servo motor. Their widespread application in industries like industrial automation, aerospace, automotive, medical equipment, and consumer electronics highlights their significance. With the future trends and opportunities, servo motors are poised to continue playing a crucial role in the field of automation and robotics. Consider the power requirements, speed, torque, efficiency, operating environment, and motor type when choosing a suitable servo motor for your application.

Author: Dream