Product Description

HangZhou CHINAMFG Electronics Co., Ltd. is a B2B and B2C online shopping mall specializing in the industrial control electrical and electronic components industry.

In order to facilitate buyers to be able to purchase globally

We are not only an industrial control electrical and electronic retailer, but also a wholesale company. We do not have a complete list of our online stores.

If you need to purchase in bulk, please contact us for a better quote.

We hope to win your trust through reliable and competitive services.

Our aim is customer satisfaction is our biggest aim !!!!

| 6ES7953-8LG11-0AA0 | 6ES7193-4CA50-0AA0 | D4SL-NSK10-LKH | E2E-X4MD1 2M |

| 6ES7953-8LG20-0AA0 | 6ES7193-4CK30-0AA0 | D4V-8104SZ-N | E2E-X14MD1 2M |

| 6ES7953-8LG30-0AA0 | 6ES7193-4JA00-0AA0 | D4V-8104Z-N | E2E-C04S12-WC-B1 2M |

| 6ES7953-8LG31-0AA0 | 6ES7193-4JA00-0AA0 | D4V-8107Z-N BY OMR | E2E-C04S12-WC-C1 2M |

| 6ES7953-8LF11-0AA0 | 6ES7193-4DL00-0AA0 | D4V-8108SZ | E2E-C04S12-WC-B1-2 2M |

| 6ES7953-8LF20-0AA0 | 6ES7193-4DL10-0AA0 | D4V-8108SZ-N | E2E-S05S12-WC-C1 2M |

| 6ES7953-8LF30-0AA0 | 6ES7193-4DE10-0AA0 | D4V-8108SZ-N | E2E-S05S12-WC-B1 2M |

| 6ES7953-8LF31-0AA0 | 6ES7193-4CE00-0AA0 | D4V-8108SZ-N BY OMR | E2E-S05S12-WC-C1-2 2M |

| 6ES7953-8LL20-0AA0 | 6ES7193-4CE10-0AA0 | D4V-8108Z-N | E2E-C03SR8-WC-C1 2M |

| 6ES7953-8LL31-0AA0 | 6ES7195-7HD80-0XA0 | D4V-8108Z-N BY OMR | E2B-M12KS04-WP-B1 |

| 6ES7195-7HB00-0XA0 | D4V-8111Z BY OMR | E2B-M12KS04-WP-B2 | |

| 6ES7131-4BF00-0AA0 | D4V-8112Z | E2B-M12KS04-WP-C1 | |

| 6ES7134-4MB02-0AB0 | 6ES7131-4BF00 | E2B-M12KS04-WP-C2 | |

| 6ES7134-4GD00-0AB0 | 6ES7132-4BF00 | E2B-M12LS04-M1-B1 OMS | E2B-S08KS02-MC-B1 OMS |

| 6ES7135-4GB01-0AB0 | 6ES7134-4GB01 | E2B-M12LS04-M1-B2 OMS | E2B-S08KS02-MC-B2 OMS |

| 6ES7135-4LB02-0AB0 | 6ES7134-4GB11 | E2B-M12LS04-M1-C1 OMS | E2B-S08KS02-MC-C1 OMS |

| 6ES7138-4DF01-0AB0 | 6ES7134-4GD00 | E2B-M12LS04-M1-C1 OMS | E2B-S08KS02-MC-C2 OMS |

| 6ES7138-4DF11-0AB0 | 6ES7135-4GB01 | E2B-S08KN04-WP-B1 2M OMS | E2B-S08KN04-MC-B1 OMS |

| 6ES7138-4CA01-0AB0 | 6ES7135-4LB02 | E2B-S08KN04-WP-B2 2M OMS | E2B-S08KN04-MC-B2 OMS |

| 6ES7138-4DA04-0AB0 | 6ES7138-4DA04 | E2B-S08KN04-WP-C1 2M OMS | E2B-M12LN05-M1-C1 OMS |

| 6ES7138-4CF03-0AB0 | 6ES7138-4CA01 | E2B-S08KN04-WP-C2 2M OMS | E2B-M12LN05-M1-C2 OMS |

| 6ES7151-3AA23-0AB0 | 6ES7151-3AA23 | E2B-M12KN05-M1-B1 OMS | E2B-M12KS02-M1-B1 OMS |

| 6ES7972-0BA52-0XA0 | 6ES7151-1AA06 | E2B-M12KN05-M1-B2 OMS | E2B-M12KS02-M1-B2 OMS |

| 6ES7972-0BA12-0XA0 | 6ES7138-4DF11 | E2B-M12KN05-M1-C1 OMS | E2B-M12KS02-M1-C1 OMS |

| 6ES7193-4GD20-0AA0 | 6ES7151-1BA02 | E2B-M12KN05-M1-C2 OMS | E2B-M12KS02-M1-C2 OMS |

| 6ES7134-4MB02-0AB0 | E2B-S08KN02-MC-B1 OMS | E2B-S08KN02-WP-B1 2M OMS | |

| 6ES7151-3BA23-0AB0 | E2B-S08KN02-MC-B2 OMS | E2B-S08KN02-WP-C1 2M OMS | |

| 6SL3120-1TE23-0AC0 | 6SL3120-2TE13-0AD0 | E2B-S08KN02-MC-C1 OMS | E2B-S08LN04-MC-B1 OMS |

| E2B-S08KN02-MC-C2 OMS | E2B-S08LN04-MC-B2 OMS | ||

| GP2501-TC11 | 3G3JZ-A4015 | D2F-F-D | CJ1W-ID261 |

| GP2501-TC41-24V | 3G3JZ-A4571 | D2F-L | CJ1W-ID262 |

| GP2400-TC41-24V | 3G3JZ-A4037 | D2FW-G271M(D) | CJ1W-MD231 |

| GP2401-TC41-24V | 3G3JZ-AB004 | D2FW-G273M | CJ1W-MD233 |

| GP2300-LG41-24V | 3G3JZ-AB007 | D2HW-A201D | CJ1W-MD261 |

| GP2301-LG41-24V | 3G3JZ-AB007 | D2MQ-1 | CJ1W-MD263 |

| GP2300-SC41-24V | 3G3JZ-AB015 | D2MV-01L22-1C3 | CJ1W-MD563 |

| GP2301-SC41-24V | 3G3JZ-AB015 | D2VW-5-1M(D)(CHN) | CJ1W-OA201 |

| GP2300-TC41-24V | 3G3MX2-A4007-ZV1 | D2VW-5L2-1M(CHN) | CJ1W-OC201 |

| GP2301-TC41-24V | 3G3MX2-A4110-ZV1 | D2VW-5L2-1M(D) | CJ1W-OC211 |

| 3G3MX2-A4150-ZV1 | D2X-C | CJ1W-OD201 | |

| GP4301TAD | 3G3MZ-AB015 | D3M-01L2 | CJ1W-OD211 |

| GP4301TADW | 3M6006 | D3V-16-3C25 BY OMI | CJ1W-OD212 |

| GP4201TAD | 3TB4322-0XB0 | D40A-1C015-F | CJ1W-OD231 |

| GP4201TADW | 3Z4S-CA STC-S133P-CS | D40A-1C5 BY OMS | CJ1W-OD232 |

| GP4401TAD | 3Z4S-LE SV-1214V | D4A-3101N | CJ1W-OD233 |

| GP4401TADW | D4A-4501N | CJ1W-OD261 | |

| GM4301TAD | 6571-1030 VS64-CBL-03M | D4A-4501N | CJ1W-OD262 |

| GM4201TAD | 61F-G 110/220VAC C | D4A-A00 | CJ1W-OD263 |

| GP4501TAD | 61F-G1N AC110/220 | D4A-C00 | CJ1W-IC101 |

| GP4501TAA | 61F-G3N AC110/220 | D4A-C00 | CJ1W-II101 |

| GP4501TADW | 61F-GP-N AC100 | D4B-2A15N | CJ1W-TER01 |

| GP4601TAA | 61F-GP-N AC220 | D4C-1202 | CJ1W-B7A22 |

| GP4601TAD | 61F-GP-N AC220 | D4C-1202 | CJ1W-INT01 |

| GP4501TMA | 61F-IN AC110/220 | D4C-1224 | CJ1W-IDP01 |

| GP4601TMA | 6ES7-216-2BD23-0XB0 | D4C-1302 | CJ1W-CLK23 |

| GP4501TMD | 8PFA | D4C-1402 | CJ1W-CRM21 |

| GP4601TMD | A165-JRM-1 | D4C-1602 | CJ1W-DRM21 |

| A-20GV2-B | D4C-3202 | CJ1W-EIP21 | |

| NS5-SQ00B-V2 | A22-01 | D4C-4332 | CJ1W-ETN21 |

| NS5-TQ11B-V2 | A22E-M-12 | D4C-6224 | CJ1W-ETN11 |

| NS5-SQ11B-V2 | A22Z-EG1 | D4CC-3060 | CJ1W-CLK21-V1 |

| NS5-SQ10B-V2 | AP-Z | D4CC-4571 | CJ1W-SCU21-V1 |

| NS5-SQ10B-ECV2 | B7AS-T6B6 | D4CC-4060 | CJ1W-SCU31-V1 |

| NS8-TV00B-V2 | B7A-T6A1 | D4DS-K1 | CJ1W-SRM21 |

| NS8-TV00B-ECV2 | BNL6 | D4DS-K2 | CJ1W-SCU41-V1 |

| NS8-TV01B-V2 | BS-1 | D4DS-K2 | CJ2M-MD211 |

| NS10-TV00B-V2 | BS-1 | D4DS-K2 | CJ2M-CPU11 |

| NS10-TV00B-ECV2 | BS-1 | D4DS-K2 | CJ2M-CPU12 |

| NS10-TV01B-V2 | D4DS-K3 | CJ2M-CPU13 | |

| NS12-TS01B-V2 | C500-CE403 | D4DS-K3 | CJ2M-CPU14 |

| NS12-TS01-V2 | C500-CE404 | D4DS-K3 | CJ2M-CPU15 |

| NS12-TS00B-V2 | C500-CE404 | D4DS-K5 | CJ2M-CPU31 |

| NS12-TS00-V2 | C500-CE404 | D4DS-K5 | CJ2M-CPU32 |

| CDHD-N | D4E-1A10N OKUMA | CJ2M-CPU33 | |

| 6ES7331-7HF01-0AB0 | CDHD-N1KW | D4E-1A20N | CJ2M-CPU34 |

| 6ES7331-7KB02-0AB0 | D4E-1A20N | CJ2M-CPU35 | |

| 6ES7331-7KF02-0AB0 | CMT3155X | D4E-2C10N | CJ1W-PA202 |

| 6ES7331-7PF01-0AB0 | CP1EB-CPURM01 | D4GL-1AFA-A | CJ1W-PA205R |

| 6ES7331-7PF11-0AB0 | CP1E-E20SDR-A | D4GS-NK1 | CJ1W-PD571 |

| 6ES7331-7NF00-0AB0 | CP1E-E30SDR-A | D4JL-2NFA-C5 | CJ1W-PD571 |

| 6ES7331-7SF00-0AB0 | CP1E-E40SDR-A | D4JL-2NFG-C5 | CJ1W-PA205C |

| 6ES7331-1KF01-0AB0 | CP1E-E60DR-A | D4JL-2RFA-C6 | CJ1M-CPU11 |

| 6ES7331-1KF02-0AB0 | CP1E-E60SDR-A | D4JL-4QFA-C6 | CJ1M-CPU12 |

| CP1E-N14DR-D | D4JL-4QFA-D6 | CJ1M-CPU13 | |

| 6ES7332-7ND02-0AB0 | CP1E-N14DT1-A | D4JL-K2 | CJ1M-CPU21 |

| 6ES7332-5HB01-0AB0 | CP1E-N14DT-D | D4JL-K3 | CJ1M-CPU22 |

| 6ES7332-5HD01-0AB0 | CP1E-N20DR-A | D4MC-2000 | CJ1M-CPU23 |

| 6ES7332-5HF00-0AB0 | CP1E-N20DT-A | D4MC-2000 | CJ1W-AD041-V1 |

| CP1E-N20DT-D | D4MC-2571 | CJ1W-AD04U | |

| 6ES7153-1AA03-0XB0 | CP1E-N30DR-A | D4MC-5000 | CJ1W-AD081-V1 |

| 6ES7153-2BA02-0XB0 | CP1E-N30DR-D -CH | D4MC-5571-N BY OMR | CJ1W-DA571 |

| 6ES7153-2BA10-0XB0 | CP1E-N30DT-A | D4MC-5040-N | CJ1W-DA041 |

| 6ES7334-0CE01-0AA0 | CP1E-N30SDT-D | D4N-2120 | CJ1W-DA08C |

| 6ES7334-0KE00-0AB0 | CP1E-N40DR-A | D4N-2122 | CJ1W-DA08V |

| 6ES7335-7HG02-0AB0 | CP1E-N40DT1-A | D4N-212G | CJ1W-MAD42 |

| 6ES7338-4BC01-0AB0 | CP1E-N40DT-A | D4N-212G | CJ1W-PTS15 |

| 6ES7350-1AH03-0AE0 | CP1E-N40SDR-A | D4N-212G | CJ1W-PTS16 |

| CP1E-N60DR-D | D4N-212H | CJ1W-PTS51 | |

| 6ES7307-1BA01-0AA0 | CP1E-N60DT1-D | D4N-2A2GR | CJ1W-PTS52 |

| 6ES7307-1EA01-0AA0 | CP1E-N60DT-A | D4N-412G | CJ1W-PH41U |

| 6ES7307-1KA02-0AA0 | CP1E-N60DT-D | D4N-8B32 | cj1W-NC113 |

| CP1H-EX40DT-D | D4NA-412G | cj1W-NC133 | |

| 6ES7315-2AG10 | CP1H-EX40DT-D | D4NA-412G | cj1W-NC213 |

| 6ES7315-2AH14-0AB0 | CP1H-EX40DT-D | D4NA-4131 | cj1W-NC233 |

| 6ES7315-2EH14-0AB0 | CP1H-X40DR-A | D4NL-1DFA-B | cj1W-NC413 |

| 6GK7343-1CX10-0XE0 | CP1H-X40DR-A | D4NL-1DFA-BS | cj1W-NC433 |

| 6GK7343-1EX30-0XE0 | CP1H-X40DR-A | D4NL-1FFA-B4S | CJ1W-TC001 |

| CP1H-X40DT-D | D4NL-2FFA-BS | CJ1W-TC002 | |

| 374-2XH01-0AA0 | CP1H-X40DT-D | D4NL-4DFA-BS | CJ1W-TC004 |

| 6ES7313-6CF03-0AB0 | CP1H-X40DT-D | D4NS-1AF | CJ1W-TC101 |

| 6ES7314-1AG140AB0 | CP1H-X40DT-D-SC | D4NS-1AF | CJ1W-CT571 |

| 6ES7317-2EK14-0AB0 | CP1H-X40DT-D-SC | D4NS-1AF | |

| CP1H-XA40DR-A | D4NS-1AF | E2E-X2E1 2M | |

| 6ES7151-1AA02-0AB0 | CP1H-XA40DR-A | D4NS-1BF | E2E-X2F1 2M |

| 6ES7151-1AA04-0AB0 | CP1H-XA40DR-A | D4NS-1BF | E2E-X2ME1 2M |

| 6ES7151-1AA05-0AB0 | CP1H-XA40DR-A | D4NS-1CF | E2E-X2D1-N 2M |

| 6ES7151-1AA06-0AB0 | CP1H-XA40DR-A | D4NS-1CF | E2E-X2D2-N 2M |

| 6ES7151-1AB02-0AB0 | CP1H-XA40DR-A | D4NS-1CF | E2E-X2D1-U-Z 2M BY OMS |

| 6ES7151-1AB05-0AB0 | CP1H-XA40DT1-D | D4NS-1CF | E2E-X20MD1 2M OMS |

| 6ES7151-3BA23-0AB0 | CP1H-XA40DT-D | D4NS-1CF | E2E-X3D1-N 2M |

| 6ES7151-3AA23-0AB0 | CP1H-XA40DT-D | D4NS-2BF | E2E-X3D2-N 2M |

| 6ES7151-1BA02-0AB0 | CP1H-XA40DT-D | D4NS-4AF | E2E-X3D1-M1G |

| 6ES7151-1CA00-0AB0 | CP1H-Y20DT-D | D4NS-4BF | E2E-X5E1 2M |

| 6ES7151-1CA00-1BL0 | D4NS-4CF | E2E-X5E2 2M | |

| 6ES7151-1CA00-3BL0 | TM-E15S26-A1 | D4NS-4CF | E2E-X5MF1 5M |

| 6ES7151-8AB00-0AB0 | 6ES7193-4CA20-0AA0 | D4NS-4DF | E2E-X1R5E1 2M |

| 6ES7151-8AB01-0AB0 | 6ES7193-4CB20-0AA0 | D4SL-CN3 | E2E-X1R5E2 2M |

| 6ES7151-8FB00-0AB0 | 6ES7193-4CC20-0AA0 | D4SL-N2FFA-D | E2E-X5ME1 2M |

| 6ES7151-8FB01-0AB0 | 6ES7193-4CD20-0AA0 | D4SL-N2GFG-D | E2E-X5ME2 2M |

| 6ES7151-7AA11-0AB0 | 6ES7193-4CG20-0AA0 | D4SL-N2HFA-D | E2E-X7D1-N 2M |

| 6ES7151-7AA13-0AB0 | 6ES7193-4CA30-0AA0 | D4SL-N2VFA | E2E-X7D1-N 5M |

| 6ES7151-7AA20-0AB0 | 6ES7193-4CB30-0AA0 | D4SL-N4RFG-D | E2E-X7D2-N 5M |

| 6ES7151-7AA21-0AB0 | 6ES7193-4CC30-0AA0 | D4SL-NK1S | E2E-X8MD1 2M |

| 6ES7151-7FA21-0AB0 | 6ES7193-4CD30-0AA0 | D4SL-NK2 | E2E-X18ME1 2M |

| 6ES7151-3BA60-0AB0 | 6ES7193-4CG30-0AA0 | D4SL-NK2 | E2EM-X8C1 2M |

| 6ES7193-4CA40-0AA0 | D4SL-NK3 | E2E-X10E1 2M | |

| 6ES7953-8LJ20-0AA0 | 6ES7193-4CF40-0AA0 | D4SL-NSK10-LK | E2E-X10ME1 2M |

| 6ES7953-8LJ30-0AA0 | 6ES7193-4CF50-0AA0 | D4SL-NSK10-LK | E2E-X10MF1 2M |

| 6ES7953-8LJ31-0AA0 | 6ES7193-4CB00-0AA0 | D4SL-NSK10-LKH | E2E-X10D1-N 5M |

| Our company specializes in industrial control PLC products, touch screen, relays, power switches, USB accessories, and is 1 of the few quality distributors/agents in China. If you have more needs. Or need more quantity. Or have other questions. Please feel free to contact us. We will give you more favorable First-class service. Let you buy with confidence ——>>Please contact us! |

|||

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

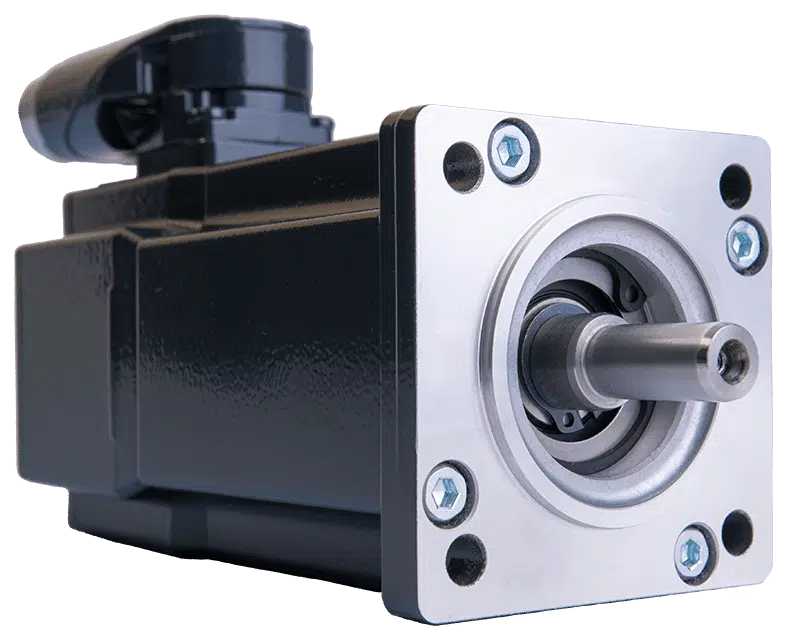

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Single-Phase |

| Function: | Control |

| Casing Protection: | Open Type |

| Number of Poles: | 8 |

| Customization: |

Available

|

|

|---|

How are servo motors used in CNC machines and other precision machining equipment?

Servo motors play a crucial role in CNC (Computer Numerical Control) machines and other precision machining equipment. They provide precise and dynamic control over the movement of various axes, enabling high-accuracy positioning, rapid speed changes, and smooth motion profiles. Here’s a detailed explanation of how servo motors are used in CNC machines and precision machining equipment:

1. Axis Control:

CNC machines typically have multiple axes, such as X, Y, and Z for linear movements, as well as rotary axes for rotational movements. Servo motors are employed to drive each axis, converting electrical signals from the CNC controller into mechanical motion. The position, velocity, and acceleration of the servo motors are precisely controlled to achieve accurate and repeatable positioning of the machine’s tool or workpiece.

2. Feedback and Closed-Loop Control:

Servo motors in CNC machines are equipped with feedback devices, such as encoders or resolvers, to provide real-time information about the motor’s actual position. This feedback is used in a closed-loop control system, where the CNC controller continuously compares the desired position with the actual position and adjusts the motor’s control signals accordingly. This closed-loop control ensures accurate positioning and compensates for any errors, such as mechanical backlash or load variations.

3. Rapid and Precise Speed Changes:

Servo motors offer excellent dynamic response, allowing CNC machines to achieve rapid and precise speed changes during machining operations. By adjusting the control signals to the servo motors, the CNC controller can smoothly accelerate or decelerate the machine’s axes, resulting in efficient machining processes and reduced cycle times.

4. Contouring and Path Tracing:

CNC machines often perform complex machining tasks, such as contouring or following intricate paths. Servo motors enable precise path tracing by accurately controlling the position and velocity of the machine’s tool along the programmed path. This capability is crucial for producing intricate shapes, smooth curves, and intricate details with high precision.

5. Spindle Control:

In addition to axis control, servo motors are also used to control the spindle in CNC machines. The spindle motor, typically a servo motor, rotates the cutting tool or workpiece at the desired speed. Servo control ensures precise speed and torque control, allowing for optimal cutting conditions and surface finish quality.

6. Tool Changers and Automatic Tool Compensation:

CNC machines often feature automatic tool changers to switch between different cutting tools during machining operations. Servo motors are utilized to precisely position the tool changer mechanism, enabling quick and accurate tool changes. Additionally, servo motors can be used for automatic tool compensation, adjusting the tool’s position or orientation to compensate for wear, tool length variations, or tool offsets.

7. Synchronized Motion and Multi-Axis Coordination:

Servo motors enable synchronized motion and coordination between multiple axes in CNC machines. By precisely controlling the servo motors on different axes, complex machining operations involving simultaneous movements can be achieved. This capability is vital for tasks such as 3D contouring, thread cutting, and multi-axis machining.

In summary, servo motors are integral components of CNC machines and precision machining equipment. They provide accurate and dynamic control over the machine’s axes, enabling high-precision positioning, rapid speed changes, contouring, spindle control, tool changers, and multi-axis coordination. The combination of servo motor technology and CNC control systems allows for precise, efficient, and versatile machining operations in various industries.

How does the accuracy of a servo motor impact the precision of a system it operates in?

The accuracy of a servo motor has a significant impact on the precision of the system in which it operates. Here’s how the accuracy of a servo motor influences the precision of the system:

1. Positioning Control:

The accuracy of a servo motor directly affects the precision of positioning control in a system. A servo motor with high accuracy can accurately and consistently reach and maintain the desired position. This precision in positioning control is crucial in applications where precise movements, such as in robotics or manufacturing processes, are required. If the servo motor lacks accuracy, it may introduce position errors, leading to reduced precision in the system’s overall operation.

2. Repeatability:

Repeatability refers to the ability of a system to consistently achieve the same position or motion repeatedly. The accuracy of a servo motor plays a vital role in achieving high repeatability. A servo motor with high accuracy will consistently return to the same position when commanded to do so. This level of repeatability is essential in applications where consistent and precise movements are necessary, such as in assembly lines or pick-and-place operations. A lack of accuracy in the servo motor can result in variations in position from one cycle to another, reducing the overall precision of the system.

3. Error Compensation:

The accuracy of a servo motor is crucial for error compensation in a system. In many applications, external factors, such as variations in load or environmental conditions, can introduce errors in the system’s operation. An accurate servo motor can help compensate for these errors by precisely adjusting its position or motion based on feedback from sensors. This error compensation capability contributes to maintaining the precision of the system, as the servo motor can continuously adjust to minimize any deviations from the desired position or trajectory.

4. System Stability:

The accuracy of the servo motor also impacts the stability of the system. A servo motor with high accuracy can achieve stable movements and maintain control over the system’s dynamics. It can respond accurately to control signals, preventing overshoot, oscillations, or erratic behaviors that can degrade system precision. On the other hand, a servo motor with lower accuracy may introduce instability or erratic movements, compromising the overall precision of the system.

5. System Calibration and Calibration:

An accurate servo motor simplifies the calibration and fine-tuning process of a system. When a system requires calibration, an accurate servo motor provides a reliable reference point for adjustments. The precise and consistent movements of the servo motor make it easier to calibrate other components or subsystems in the system, ensuring that the entire system operates with the desired precision. If the servo motor lacks accuracy, it can be challenging to calibrate the system effectively, resulting in reduced precision in the system’s operation.

In summary, the accuracy of a servo motor has a direct impact on the precision of the system it operates in. An accurate servo motor enables precise positioning control, high repeatability, effective error compensation, system stability, and simplified calibration processes. These factors collectively contribute to achieving the desired precision in the system’s operation. Therefore, selecting a servo motor with the appropriate level of accuracy is crucial for ensuring the overall precision and performance of the system.

What are the key advantages of using servo motors in industrial applications?

Servo motors offer several key advantages that make them highly beneficial for a wide range of industrial applications. Here are some of the main advantages of using servo motors:

1. Precise Positioning:

Servo motors excel at precise positioning control. They can accurately move to specific angles or positions with high repeatability. This level of precision is crucial in applications where accurate and consistent positioning is required, such as robotics, CNC machining, and assembly lines.

2. High Torque at Various Speeds:

Servo motors are designed to deliver high torque output across a range of speeds. They can generate significant torque even at low speeds, enabling efficient operation in applications that require both high torque and precise control, such as lifting heavy loads or performing intricate movements.

3. Fast Response Times:

Servo motors have fast response times, meaning they can quickly accelerate, decelerate, and change direction in response to control signals. This responsiveness is essential in applications where rapid and dynamic motion control is needed, such as industrial automation, robotics, and production line equipment.

4. Closed-Loop Control:

Servo motors operate in a closed-loop control system, where feedback from position sensors is continuously used to adjust the motor’s behavior. This feedback control mechanism enables accurate tracking of the desired position and compensates for any disturbances or variations that may occur during operation. It enhances the motor’s accuracy, stability, and performance.

5. Wide Range of Sizes and Power Ratings:

Servo motors are available in a wide range of sizes and power ratings, making them suitable for diverse industrial applications. Whether it’s a small motor for precision tasks or a large motor for heavy-duty operations, there are servo motor options to meet various requirements.

6. Energy Efficiency:

Servo motors are designed to be energy-efficient. They typically have high power density, which means they can deliver a significant amount of torque per unit of size and weight. This efficiency helps reduce power consumption, lowers operating costs, and contributes to a greener and more sustainable industrial environment.

7. Flexibility and Adaptability:

Due to their versatility, servo motors can be easily integrated into different systems and applications. They can be combined with various control systems, sensors, and communication protocols to provide seamless integration and compatibility with existing industrial setups. This flexibility allows for customized and scalable solutions tailored to specific industrial requirements.

8. Durability and Reliability:

Servo motors are known for their durability and reliability, even in demanding industrial environments. They are built to withstand harsh conditions such as high temperatures, vibrations, and dust. This robust construction ensures long-term operation and minimizes downtime, contributing to increased productivity and reduced maintenance costs.

In summary, the key advantages of using servo motors in industrial applications include precise positioning, high torque at various speeds, fast response times, closed-loop control for accuracy and stability, a wide range of sizes and power ratings, energy efficiency, flexibility, and durability. These advantages make servo motors highly valuable for industries that require precise motion control, such as robotics, manufacturing, automation, CNC machining, and many others.

editor by CX 2024-05-09