Product Description

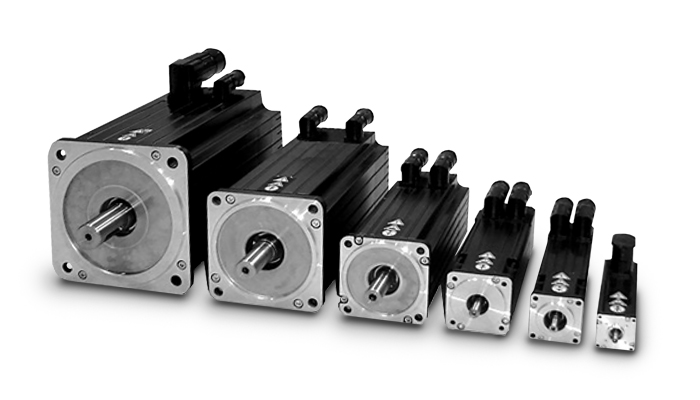

High Torque 219mm 1800W 3000RPM 6NM 18NM 220V Ac Servo Motor And Driver With 2500PPR Encoder

SZGH-11180DC(H) is 1800W servo motor ,optimizing design, compact, beautiful contour, long-term continuous working in rated working mode and economic type

Packing list :

1) SZGH-11180DC(H) 1.8kw servo motor -1pcs

2) SZGH-SD2026E 220v servo driver – 1pcs

3) SZGH1MX-5M 5meter motor cables -1pcs

4) SZGH1EX-5M 5 meter encoder cables -1 pcs

5) Manual -1pcs

Pls tell us at first time when you need :

1) Brake motor

2) 2500PPR encoder

3) long cables

Product Description

|

Rated Power |

1800W |

|

Rated torque |

6NM |

| Rated Speed | 3000RPM |

|

Rated Curret |

6A |

|

Rated Voltage |

220V |

|

Encoder |

17bit |

Description of Driver

Input Power : Single Three Phase AC220V-15%~+10% SO/60HZ

Control model :

0: Position Control; 1:Speed Control;

2: Torque Control; 3:Position/Speed Control;

4·PositionTorque Control: 5:Speed Torque Control

Protective Function : Over-speed Over-voltage Under-voltage Over-current OverloadEncoder Error/ Control Power Eror/ Position Offset Eror

Driver Load : Less than 3times of rotor inertia

Display : 5 bits LED indicator display 4 Operate keys

Communication : RS485

Position Control : Input Model , Electric Ratio

Product Parameters

Certifications

Packaging & Shipping

1.Industrial packing: plastic bag +foam boxes+ carton +wooden pallets 2.Commercial packing: plastic bag+ foam boxes + carton

3.As the clients requirement

Delivery Detail: Normally ready goods and stock within 2- 5days

Company Profile

HangZhou CHINAMFG Automation CO.,LTD (Formerly known as ‘HangZhou CHINAMFG Automation Co.,Limited(Built in 19 November 2571)’) is 1 of the leading CNC & automatic company in China, specialized in designing projects, marketing, and oversea trading, having extensive experience in CNC package solution, Our focus has been on providing the high quality of Industrial robot arm Lathe CNC system, Milling CNC system, Engraving CNC system, Grinding & router CNC system, Motor & driver, Spindle servo motor & driver, Gear reducer.

SZGH’ products have been in working with a wide variety of CNC machinery and automatic processing equipment with high performance and good precision, stably. We have now established a reliable structure , our experienced engineers and technicians are able to provide professional consultancy and offer you most suitable CNC application solution.

Our strict quality control measures guarantee excellent reliability and high standard of quality. Utilizing advanced CNC machinery to test every product, 100 percent inspection is made before packaging and shipment. Moreover, We also offer flexible lead times to support your business.

We have a large number of customers across Asia, America, the Middle East, Europe, South America, and Africa. Specially we already built own business corporate group in Middle East market.

Our Advantages

After Sales Service

Best & Professional after- sales supports

Our company have very professional engineers teams ;

We can provide the professional after -sales service to our all clients ;

Here is our engineer Mike solved the problems for our customer ;

Best supports !! Quicly reply !!

Buy at ease , use at ease !!!

FAQ

Q: Do you support customized manufacturing?

A: Yes,we can customized manufacturing according to customer’s requirment. We support to OEM your own company display interface

and logo.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to

quantity.10-20 days if customized manufacturing.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample with sample price.

Q: What is your terms of payment ?

A: Payment=1000USD, 70% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machine Tool |

|---|---|

| Speed: | Variable Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving, Control |

| Casing Protection: | Explosion-Proof Type |

| Number of Poles: | 4 |

| Customization: |

Available

|

|

|---|

How does the cost of servo motors vary based on their specifications and features?

The cost of servo motors can vary significantly based on their specifications and features. Several factors influence the price of servo motors, and understanding these factors can help in selecting the most cost-effective option for a specific application. Let’s explore in detail how the cost of servo motors can vary:

1. Power Rating:

One of the primary factors affecting the cost of a servo motor is its power rating, which is typically measured in watts or kilowatts. Higher power-rated servo motors generally cost more than lower-rated ones due to the increased materials and manufacturing required to handle higher power levels. The power rating of a servo motor is determined by the torque and speed requirements of the application. Higher torque and speed capabilities often correspond to higher costs.

2. Torque and Speed:

The torque and speed capabilities of a servo motor directly impact its cost. Servo motors designed for high torque and high-speed applications tend to be more expensive due to the need for robust construction, specialized materials, and advanced control electronics. Motors with higher torque and speed ratings often require more powerful magnets, larger windings, and higher precision components, contributing to the increase in cost.

3. Frame Size:

The physical size or frame size of a servo motor also plays a role in determining its cost. Servo motors come in various frame sizes, such as NEMA (National Electrical Manufacturers Association) standard sizes in North America. Larger frame sizes generally command higher prices due to the increased materials and manufacturing complexity required to build larger motors. Smaller frame sizes, on the other hand, may be more cost-effective but may have limitations in terms of torque and speed capabilities.

4. Feedback Mechanism:

The feedback mechanism used in a servo motor affects its cost. Servo motors typically employ encoders or resolvers to provide feedback on the rotor position. Higher-resolution encoders or more advanced feedback technologies can increase the cost of the motor. For example, servo motors with absolute encoders, which provide position information even after power loss, tend to be more expensive than those with incremental encoders.

5. Control Features and Technology:

The control features and technology incorporated into a servo motor can influence its cost. Advanced servo motors may offer features such as built-in controllers, fieldbus communication interfaces, advanced motion control algorithms, or integrated safety functions. These additional features contribute to the cost of the motor but can provide added value and convenience in certain applications. Standard servo motors with basic control functionality may be more cost-effective for simpler applications.

6. Brand and Reputation:

The brand and reputation of the servo motor manufacturer can impact its cost. Established and reputable brands often command higher prices due to factors such as quality assurance, reliability, technical support, and extensive product warranties. While motors from less-known or generic brands may be more affordable, they may not offer the same level of performance, reliability, or long-term support.

7. Customization and Application-Specific Requirements:

If a servo motor needs to meet specific customization or application-specific requirements, such as specialized mounting options, environmental sealing, or compliance with industry standards, the cost may increase. Customization often involves additional engineering, design, and manufacturing efforts, which can lead to higher prices compared to off-the-shelf servo motors.

It’s important to note that the cost of a servo motor is not the sole indicator of its quality or suitability for a particular application. It is essential to carefully evaluate the motor’s specifications, features, and performance characteristics in relation to the application requirements to make an informed decision.

In summary, the cost of servo motors varies based on factors such as power rating, torque and speed capabilities, frame size, feedback mechanism, control features and technology, brand reputation, and customization requirements. By considering these factors and comparing different options, it is possible to select a servo motor that strikes the right balance between performance and cost-effectiveness for a specific application.

What factors should be considered when selecting a servo motor for a specific application?

When selecting a servo motor for a specific application, several factors need to be considered. These factors help ensure that the chosen servo motor meets the requirements and performs optimally in the intended application. Here are some key factors to consider:

1. Torque and Power Requirements:

One of the primary considerations is the torque and power requirements of the application. The servo motor should be able to generate sufficient torque to handle the load and overcome any resistance or friction in the system. Additionally, the power rating of the motor should match the power supply available in the application. It is essential to evaluate the torque-speed characteristics of the servo motor to ensure it can deliver the required performance.

2. Speed and Acceleration:

The required speed and acceleration capabilities of the servo motor should align with the application’s needs. Different applications have varying speed and acceleration requirements, and the servo motor should be able to meet these demands. It is crucial to consider both the maximum speed that the motor can achieve and the time it takes to accelerate or decelerate to specific speeds. Evaluating the servo motor’s speed-torque characteristics and acceleration capabilities is necessary for selecting the right motor.

3. Positioning Accuracy and Repeatability:

The desired positioning accuracy and repeatability of the application play a significant role in servo motor selection. If precise positioning is crucial, a servo motor with high accuracy and low positioning errors should be chosen. The feedback mechanism, such as encoders or resolvers, should provide the required resolution to achieve the desired accuracy. Repeatability, the ability to consistently reach the same position, should also be considered, especially in applications where repetitive movements are necessary.

4. Environmental Conditions:

The environmental conditions in which the servo motor will operate should be taken into account. Factors such as temperature extremes, humidity, dust, and vibration can affect the motor’s performance and lifespan. In harsh environments, it may be necessary to choose a servo motor with appropriate protection ratings, such as IP (Ingress Protection) ratings, to ensure reliable operation and longevity.

5. Control System Compatibility:

The compatibility of the servo motor with the control system used in the application is crucial. The motor should be compatible with the control signals and communication protocols employed in the system. This includes considerations such as voltage compatibility, control signal types (analog, digital, pulse), and communication interfaces (such as Ethernet, CAN, or Modbus). Ensuring compatibility will facilitate seamless integration and efficient control of the servo motor within the application.

6. Size and Weight Constraints:

The physical size and weight limitations of the application should be considered when selecting a servo motor. The motor’s dimensions should fit within the available space, and its weight should not exceed the application’s weight capacity. Compact and lightweight servo motors may be preferred in applications where space is limited or weight is a critical factor.

7. Cost Considerations:

The cost of the servo motor and its overall value for the application should be evaluated. It is essential to consider the initial purchase cost as well as the long-term maintenance and operational costs. While cost is a factor, it should not be the sole determining factor, as compromising on quality or performance may lead to suboptimal results.

By considering these factors, one can make an informed decision when selecting a servo motor for a specific application. It is recommended to consult with manufacturers or experts in the field to ensure the chosen servo motor meets the application’s requirements and provides reliable and efficient performance.

Can you explain the difference between a servo motor and a regular electric motor?

A servo motor and a regular electric motor are both types of electric motors, but they have distinct differences in terms of design, control, and functionality.

A regular electric motor, also known as an induction motor or a DC motor, is designed to convert electrical energy into mechanical energy. It consists of a rotor, which rotates, and a stator, which surrounds the rotor and generates a rotating magnetic field. The rotor is connected to an output shaft, and when current flows through the motor’s windings, it creates a magnetic field that interacts with the stator’s magnetic field, resulting in rotational motion.

On the other hand, a servo motor is a more specialized type of electric motor that incorporates additional components for precise control of position, speed, and acceleration. It consists of a regular electric motor, a sensor or encoder, and a feedback control system. The sensor or encoder provides feedback on the motor’s current position, and this information is used by the control system to adjust the motor’s behavior.

The key difference between a servo motor and a regular electric motor lies in their control mechanisms. A regular electric motor typically operates at a fixed speed based on the voltage and frequency of the power supply. In contrast, a servo motor can be controlled to rotate to a specific angle or position and maintain that position accurately. The control system continuously monitors the motor’s actual position through the feedback sensor and adjusts the motor’s operation to achieve the desired position or follow a specific trajectory.

Another distinction is the torque output of the motors. Regular electric motors generally provide high torque at low speeds and lower torque at higher speeds. In contrast, servo motors are designed to deliver high torque at both low and high speeds, which makes them suitable for applications that require precise and dynamic motion control.

Furthermore, servo motors often have a more compact and lightweight design compared to regular electric motors. They are commonly used in applications where precise positioning, speed control, and responsiveness are critical, such as robotics, CNC machines, automation systems, and remote-controlled vehicles.

In summary, while both servo motors and regular electric motors are used to convert electrical energy into mechanical energy, servo motors offer enhanced control capabilities, precise positioning, and high torque at various speeds, making them well-suited for applications that require accurate and dynamic motion control.

editor by CX 2024-03-01